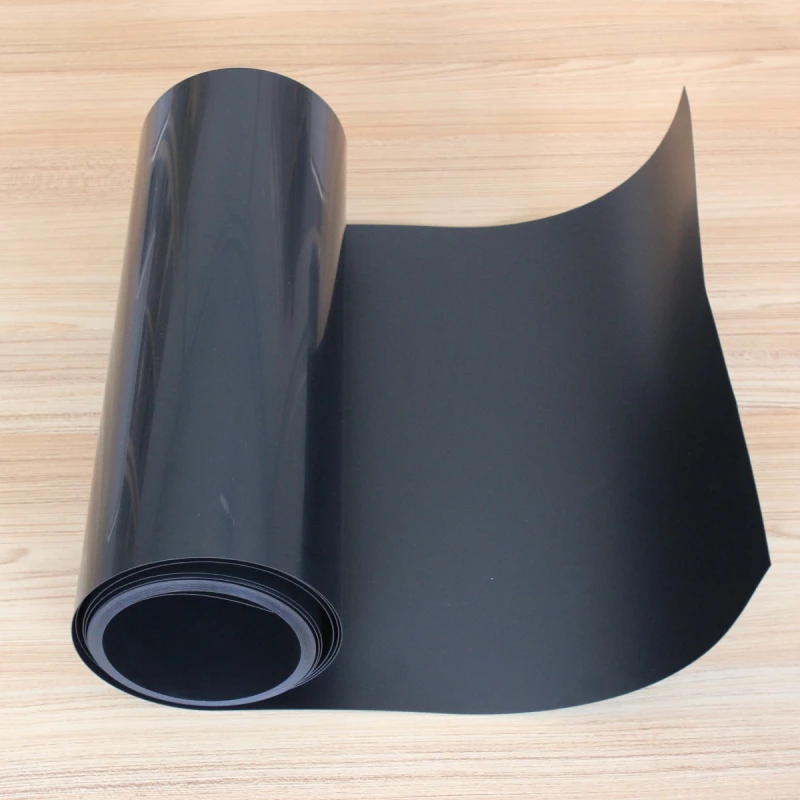

PP Conductive Sheet Roll

Antistatic materials are essential in modern industrial manufacturing and electronic packaging. Conductive PP plastic sheet roll is a thermoplastic material with excellent conductive properties and antistatic effects. The resistance value is between 10⁴-10⁶ Ω, which can effectively release static electricity and protect sensitive electronic components and high-precision instruments from static damage.

W.hat is conductive PP plastic sheet?

Conductive PP (polypropylene) plastic sheet is based on PP resin. By adding conductive carbon powder, carbon nanotubes or conductive masterbatch, it has stable conductivity and excellent physical and mechanical properties. Its main features are light weight, strong chemical resistance, high mechanical strength, environmental protection and recyclability. It is particularly suitable for electronics, medical and industrial packaging.

Сpecifications of PP sheet

| Product Name | Conductive PP sheet roll |

| Resistance Value (Ω) | 10^4-10^6 |

| Shape | Roll/Sheet |

| Thickness | 0.2~2.0mm |

| Width | 300~850mm |

| PP Roll Diameter | ≤38 inch |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Quality | 100% virgin |

| Color | Clear, Natural, Black, White, Color, Customized according to needs. |

| Surface Treatment | Matte, Glossy. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die cutting. |

| Hardness | Rigid / Semi-rigid |

Тypes of PP sheets we offer

| PP sheet type | Width (mm) | Thickness (mm) | Color | Resistance value (Ω) |

| PP normal sheet | 300-850 | 0.2-2.0 | Any/Customized | / |

| PP sheet for frozen tray | Any/Customized | / | ||

| PP sheet for cooked food tray | Any/Customized | / | ||

| PP/PE | Any/Customized | / | ||

| PP/EVOH/PP | Any/Customized | / | ||

| PP conductive sheet | Any/Customized | 104-106 |

Вharacteristics of conductive PP plastic sheet

Excellent conductive performance: The resistance value ranges from 10⁴-10⁶ Ω, which can effectively release static electricity and prevent damage to electronic components.

Lightweight and high strength: Compared with traditional conductive plastic materials, PP sheets are lighter while maintaining high impact strength and folding resistance.

Strong chemical resistance: Acid and alkali resistance, solvent resistance, suitable for all kinds of harsh environments.

Environmentally friendly and recyclable: PP material is non-toxic and harmless, recyclable, and meets the requirements of sustainable development.

Good thermoforming: Suitable for vacuum forming, stamping, bending and other processing methods, can be used to customize various packaging shapes.

Аdvantages of conductive PP plastic sheet

🔹 More efficient static discharge: More conductive than ordinary anti-static PP, suitable for more stringent static control requirements.

🔹 Longer service life: Compared with surface coating anti-static materials, the conductive properties of conductive PP are evenly distributed and will not fail due to wear.

🔹 Wider application range: It can be used in multiple industries such as electronics, automobiles, and medical care to meet the needs of various scenarios.

🔹 More cost-effective: Compared with conductive PS, conductive ABS and other materials, PP materials have lower costs and excellent performance and processing adaptability.

Аpplication of PP plastic sheet rolls

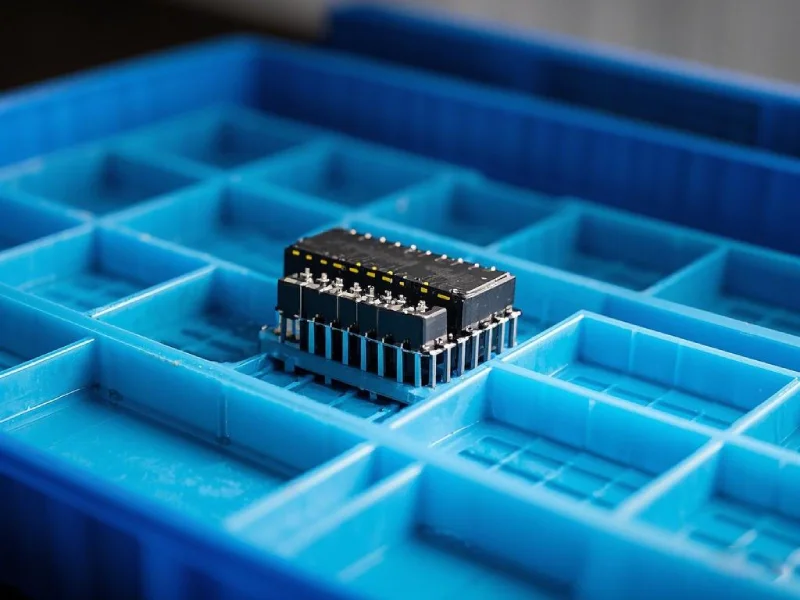

📌 Electronic packaging: IC tray, PCB board transport packaging, electronic component buffer packaging

📌 Medical industry: biopharmaceutical equipment packaging, anti-static medical supplies packaging

📌 Automobile industry: transportation and storage of automotive electronic accessories

📌 Logistics and transportation: anti-static turnover boxes, conductive trays, partitions, etc.

📌 Industrial manufacturing: clean room anti-static partitions, workbench gaskets, etc.

ФонAQS

Ведущийelate Products

АБой Шенган

Shengan (Shanghai) New Materials Co., Ltd - ваш поставщик решений для домашних животных.

Основанный в 2018 году в Шанхае, Шенган специализируется на высококачественном Домашние листы и Термоформирование, Служба, такие как электроника, продукты питания, косметика и медицинская. Благодаря объекту площадью 120 000 кв. Сертификаты ISO9001, GRS и SGSПолем

Ключевые предложения

- Домашние листы: APET, RPET (переработанный), ESD антистатический, кляп.

- Машины: Термоформирование, чашка и блистерные машины.

- Пользовательские решения: Услуги OEM, адаптированные к вашим потребностям.

Глобальный охват

- Экспорт в 70+ стран (Америка, Европа, Азия, Африка).

- Годовые продажи превышают 10 миллионов долларов, с 71% -80% объемом экспорта.

Приверженность совершенству

- Первоначальный клиент подход: Комплексная гарантия поддержки и удовлетворения.

- Устойчивые практики: Экологичные материалы и сертифицированные GRS производство.