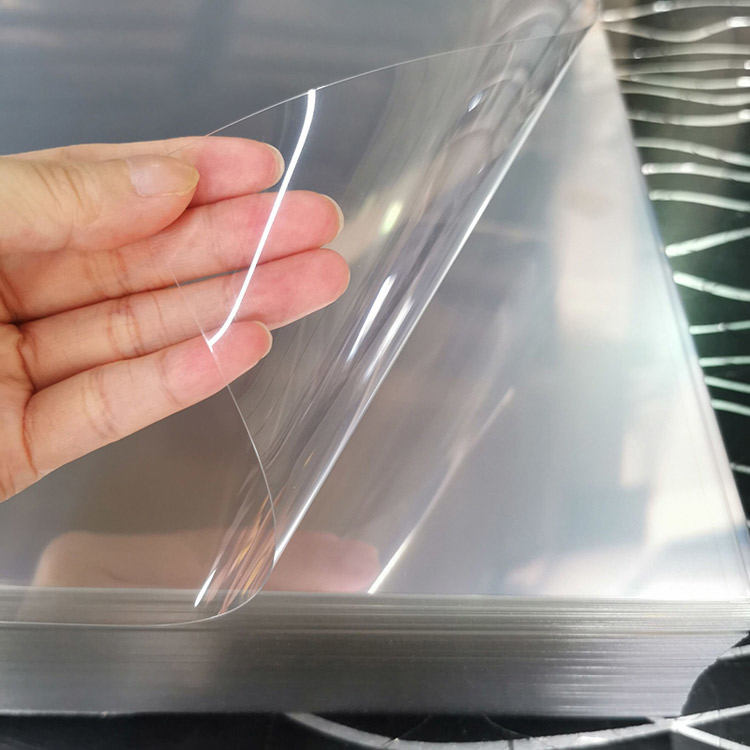

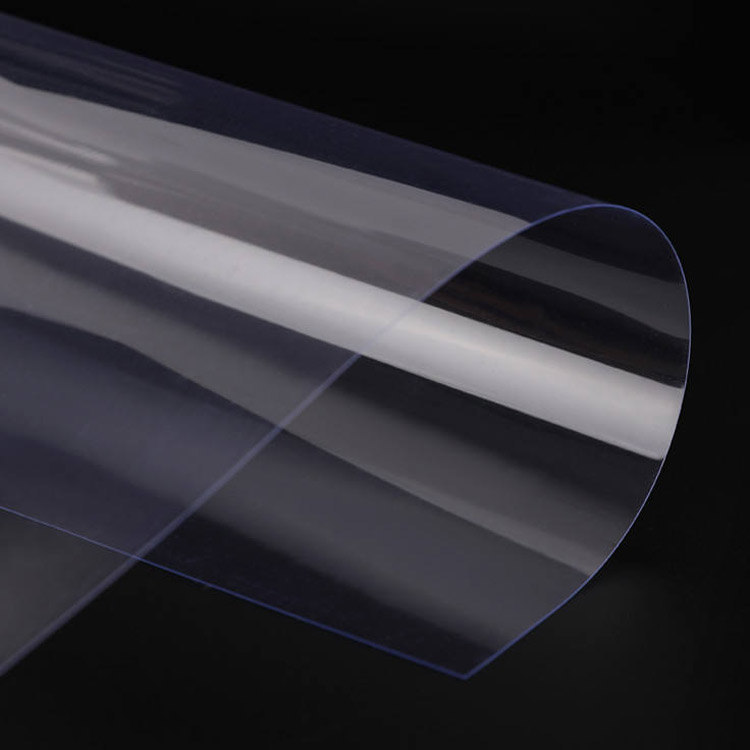

ПЭТ лист для вакуумной формовки

PET Sheet offers excellent light transmittance and mechanical strength, high resistance to oxygen and water vapor, customized cutting and special functional additives, high-end customization. ABA three-layer co-extrusion structure, in line with EFSA and FDA food safety certification, widely used in food and beverage packaging industry

СТехнические характеристики рулона ПЭТ-листа

| Категория продукта | APET, GAG, RPET, ПЭТ/ПЭ и т. д. |

| Форма | Рулон/Лист |

| Толщина | 0.18~1,8 мм |

| Ширина | 300~1400 мм |

| Качество | Девственный/переработанный |

| Процент содержания RPET | 30%-100% |

| ДОМАШНИЙ ПИТОМЕЦ Диаметр рулона | ≤38 дюймов |

| Цвет | Прозрачный, белый, синий, коричневый, розовый, зеленый, желтый или индивидуальный |

| Производительность | Защита от запотевания, защиты от электростатического разряда (антистатическая, проводящая, рассеивающая статическое электричество), короны, печати, покрытия, ударопрочности, водонепроницаемости, маслостойкости, защиты от ультрафиолета и т. д. |

| Упаковка | Полиэтиленовая пленка внутри + крафт снаружи + поддон (диаметр бумажной трубки: 76 мм, толщина: 10 мм) |

| Технология обработки | Термоформование, вакуумное блистерное формование, высечка |

| Properties | UNIT | METHOD | Virgin PET | Pre-consumer/Post Recycled PET | |||

|---|---|---|---|---|---|---|---|

| Data | (ASTM) | 100% PET | RPET 25% | RPET 30% | |||

| Thickness Tolerance | %/mm | / | ±5% | ±5% | ±5% | ||

| Thickness Range | mm | / | 0.18 – 1.8 | 0.18 – 1.8 | 0.12 – 1.8 | ||

| Width Tolerance | mm | / | ±2mm | ±2mm | ±2mm | ||

| Width Range | mm | / | 300 – 1400 | 300 – 1400 | 300 – 1400 | ||

| Weight Tolerance | % | / | ±3% | ±3% | ±3% | ||

Main features

- Excellent ffavour barrier properries

- Easy thermoforming characteristics

- Excellent impact resistance

- High transparency and gloss

- ABA Multi-layer

- Tighter thickness tolerances and more precise

- Fully automatic PLC production equipment, with PET sheet stable perrormance

- On-line detection system reduces the failure rate and stabilizes the quality

Аdvantages of PET plastic sheet rolls

(1) Excellent food safety performance

PET material itself does not contain harmful substances such as BPA and plasticizers, ensuring food health and safety.

After strict production process control, it meets international food safety standards, such as FDA (U.S. Food and Drug Administration), EU 10/2011 (EU Food Contact Materials Regulation), etc.

(2) High transparency and good display effect

The light transmittance of PET sheet can reach more than 90%, making packaged food more attractive and convenient for consumers to check product quality.

It can be used for high-end food packaging to increase product added value and market competitiveness.

(3) Excellent mechanical properties

It has good impact resistance and tensile strength, is not easy to break during transportation and storage, and ensures food safety.

Lightweight design effectively reduces the cost of packaging materials, while facilitating transportation and storage.

(4) Strong temperature resistance, suitable for a variety of food packaging needs

PET sheet can withstand refrigerated environments (-40℃) and is suitable for frozen food packaging, such as cold drinks, dairy products, frozen meat, etc.

It remains stable in high temperature environment (within 70℃) and can be used for room temperature food packaging, such as cakes, nuts, candies, etc.

(5) Easy to process and can undergo a variety of secondary treatments

It is suitable for processing technologies such as thermoforming, blistering, stamping, bending, etc., and can be used to make food packaging boxes and blister trays of different shapes.

The surface can be printed, coated, metallized, etc. to meet personalized packaging needs.

(6) Environmentally friendly and recyclable, in line with the trend of sustainable development

PET plastic is a 100% recyclable environmentally friendly material. After use, it can be remade into food packaging materials to reduce plastic pollution.

It complies with global green environmental protection policies and is favored by the market and consumers.

ПТип листа ET, который мы предлагаем

| Тип листа ПЭТ | Ширина (мм) | Толщина (мм) | Цвет | Значение сопротивления (Ом) |

| ПЭТ с силиконовым покрытием | 300-1400 | 0.18-1,8 | Прозрачный/Другие | / |

| лист РПЭТ | Прозрачный/Другие | / | ||

| лист кляпа | Прозрачный/Другие | / | ||

| ПЭТ против запотевания | Прозрачный/Другие | / | ||

| Ударопрочный ПЭТ | Прозрачный/Другие | / | ||

| ПЭТ ламинирование ПЭ | Прозрачный/Другие | / | ||

| ПЭТ-лист для электронного | ||||

| Проводящий ПЭТ | 300-1400 | 0.18-1,8 | Прозрачный/Другие | 104-106 |

| Полупроводниковый ПЭТ | Прозрачный/Другие | 106-109 | ||

| Антистатический ПЭТ | Прозрачный/Другие | 109-1011 | ||

| ПЭТ с покрытием | Прозрачный/Другие | 103-106 | ||

АБой Шенган

Компания ShengAn (Шанхай) New Materials Co., Ltd – Ваш партнер в области решений для пластиковой упаковки

Компания ShengAn, основанная в 2018 году в Шанхае, Китай, является ведущим мировым партнером, предоставляющим комплексные решения для индустрии пластиковой упаковки. От высокоэффективных материалов до готовой продукции и оборудования, мы расширяем возможности бизнеса по всему миру.

Наши комплексные решения

- Усовершенствованные пластиковые листы: Мы специализируемся на полном спектре термопластических листов, в том числе APET, RPET (переработанный ПЭТ), PETG, PP, PS, GAG и ESD-безопасность. материалы, предназначенные для разнообразных и требовательных применений.

- Готовая пищевая продукция: Мы не ограничиваемся сырьем и производим высококачественную упаковку по индивидуальному заказу, такую как пищевые пластиковые лотки, одноразовые стаканчики & крышки и термоформованная блистерная упаковка по индивидуальному заказу.Полем

- Надежное оборудование & Оборудование: Для завершения вашего производственного цикла мы поставляем и поддерживаем эффективные Машины для термоформования ПЭТ-стаканов и блистерные упаковочные машиныПолем

Сертифицированное качество, мировые стандарты

Наша приверженность подтверждена международными сертификатами, такими как ISO 9001, FSSC, FDA и GRS., гарантируя, что наша продукция соответствует самым строгим требованиям к качеству, безопасности пищевых продуктов и устойчивому развитию.

Почему стоит сотрудничать с ShengAn?

- Сквозная интеграция: Мы оптимизируем вашу цепочку поставок, предлагая все, от материалов до оборудования, обеспечивая согласованность, эффективность и экономичность.

- Приверженность качеству & Безопасность: Наша продукция подтверждена строгими международными сертификатами, в том числе ISO 9001, ISO 14001, FSSC, FDA, HACCP и GRS (для RPET), гарантируя, что продукция соответствует самым высоким мировым стандартам.

- Проверенное производственное совершенство: Благодаря нашим стратегическим производственным базам в Шанхае мы обладаем способностью предоставлять масштабируемые, надежные решения и бесперебойное управление цепочками поставок для клиентов по всему миру.