Anti-block PET Sheet

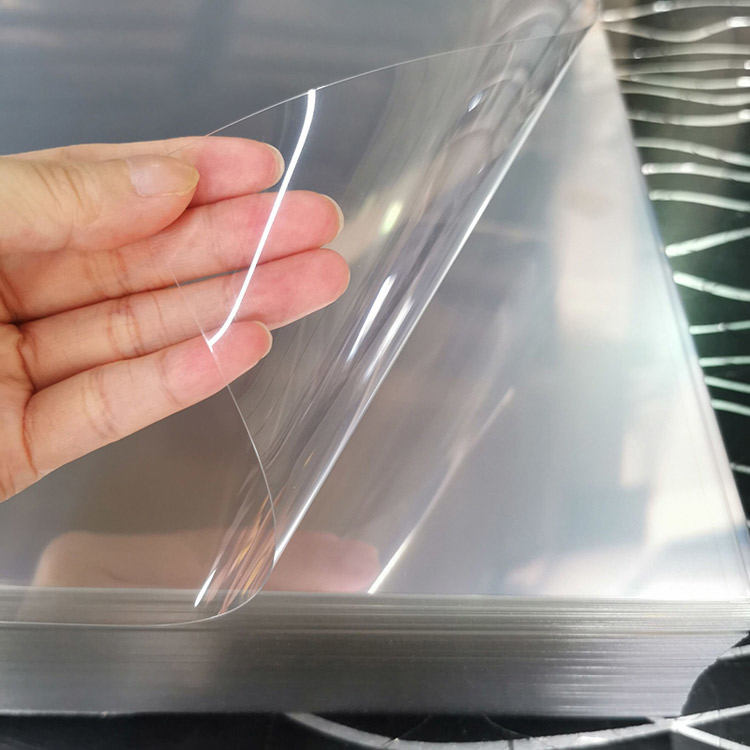

Intro of Anti-block PET Sheet

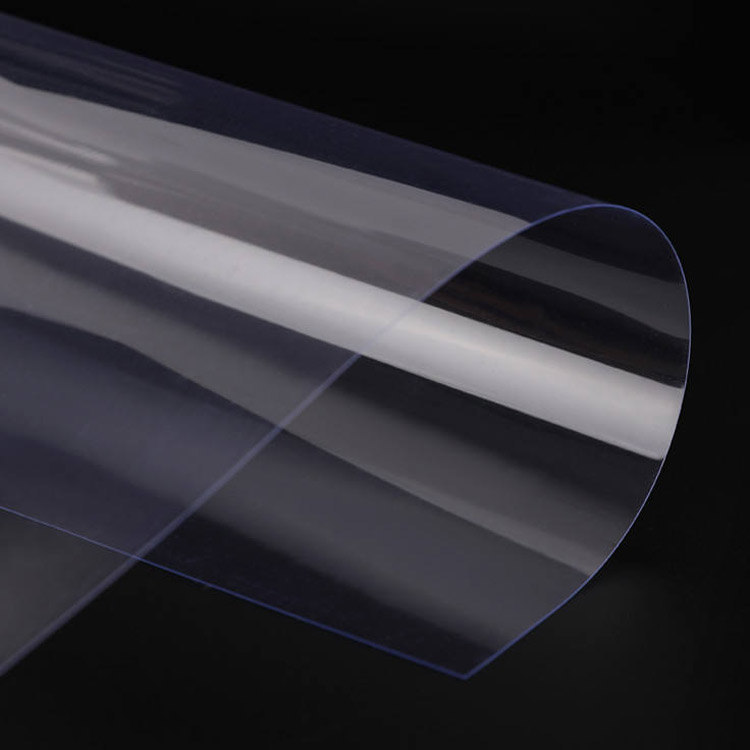

Anti-block PET sheet is a specially treated polyethylene terephthalate (PET) film or sheet, mainly used to prevent blocking of materials when stacking or winding. Anti-blocking technology is usually implemented in two ways:

External Silicone Coating: Coat a layer of silicone oil on the PET surface to reduce the surface friction coefficient.

Internal Slip Additive: Add a slip agent (such as silica, silicone or wax) during the production process to make it evenly distributed in the PET substrate.

The product thickness usually ranges from 0.18mm to 1.7mm and is suitable for industrial applications that require high transparency, temperature resistance and anti-blocking properties.

| Specification | Silicone oil-coated PET | Embedded anti-block PET |

| Color | Any customized color | Any customized color |

| Material | PET/R-PET | PET/R-PET |

| Surface treatment | Silicon-coated | Non-silicon / Embedded |

| Width | 250-1400(mm) | 250-1400(mm) |

| Thickness | 0.18-1.7(mm) | 0.18-1.7(mm) |

| Density | 1.34g/cm3 | 1.34g/cm3 |

Features of Anti-block PET Sheet

Excellent anti-blocking performance: effectively prevent PET sheets from sticking when stacking or winding.

High transparency (for external silicone oil coating): The silicone oil coating is extremely thin and has almost no effect on optical properties.

Good slipperiness (internal type): Low friction coefficient, easy processing and separation.

Temperature resistance: PET substrate can withstand -40°C to 150°C (higher in the short term).

Chemical stability: Resistant to oil, grease, weak acid and weak alkali, suitable for a variety of industrial environments.

High mechanical strength: Anti-stretching and anti-puncture, suitable for die-cutting, stamping and other processing methods.

Advantages of Anti-block PET Sheet

| Comparison item | External silicone oil type | Internal slip type |

| Anti-stick effect | Excellent, suitable for high-demand scenarios | Good, may slightly decrease with long-term use |

| Transparency | High (very thin coating) | May be slightly lower (depending on additives) |

| Permanence | May be weakened by friction or cleaning | More durable (slip agent is evenly distributed) |

| Applicable process | Suitable for short-term anti-stick needs | Suitable for long-term storage or high temperature environment |

| Cost | Higher (additional coating process required) | Lower (direct production) |

Comprehensive advantages:

✔ Reduce production downtime (avoid material adhesion affecting processing)

✔ Improve automated packaging efficiency (sheets are easy to separate)

✔ Applicable to industries with high cleanliness requirements such as food and medical

Applications of Anti-block PET Sheet

Packaging industry: food tray gasket, high-end gift box anti-sticking layer

Electronic industry: display screen protective film, lithium battery separator

Medical industry: tablet packaging, medical device anti-sticking pad

Industrial materials: composite material isolation film, die-cutting and stamping pad

Printing industry: high-gloss PET printing anti-sticking backing paper

FAQ

PET sheet type we offer

| PET sheet type | Width (mm) | Thickness (mm) | Color | Resistance value (Ω) |

| Silicon-coated PET | 300-1400 | 0.18-2.0 | Transparent/Others | / |

| RPET sheet | Transparent/Others | / | ||

| GAG sheet | Transparent/Others | / | ||

| Anti-fog PET | Transparent/Others | / | ||

| High impact PET | Transparent/Others | / | ||

| PET lamination PE | Transparent/Others | / | ||

| PET sheet for electronic | ||||

| Conductive PET | 300-1400 | 0.18-2.0 | Transparent/Others | 104-106 |

| Semi-conductive PET | Transparent/Others | 106-109 | ||

| Anti-stactic PET | Transparent/Others | 109-1011 | ||

| Coated PET | Transparent/Others | 103-106 | ||

АБой Шенган

Shengan (Shanghai) New Materials Co., Ltd - ваш поставщик решений для домашних животных.

Основанный в 2018 году в Шанхае, Шенган специализируется на высококачественном Домашние листы и Термоформирование, Служба, такие как электроника, продукты питания, косметика и медицинская. Благодаря объекту площадью 120 000 кв. Сертификаты ISO9001, GRS и SGSПолем

Ключевые предложения

- Домашние листы: APET, RPET (переработанный), ESD антистатический, кляп.

- Машины: Термоформирование, чашка и блистерные машины.

- Пользовательские решения: Услуги OEM, адаптированные к вашим потребностям.

Глобальный охват

- Экспорт в 70+ стран (Америка, Европа, Азия, Африка).

- Годовые продажи превышают 10 миллионов долларов, с 71% -80% объемом экспорта.

Приверженность совершенству

- Первоначальный клиент подход: Комплексная гарантия поддержки и удовлетворения.

- Устойчивые практики: Экологичные материалы и сертифицированные GRS производство.