Food Grade PET Plastic Sheet Roll

features of Food Grade PET Plastic Sheet Roll

PET (polyethylene terephthalate) plastic sheet is widely used in the field of food packaging due to its excellent physical properties and food safety. Food grade PET sheet rolls are strictly controlled by the production process and meet international food contact safety standards to ensure the hygiene and safety of food packaging.

specifications of PET sheet

| 製品カテゴリ | APET, GAG, RPET, PET/PE, etc. |

| 形 | ロール/シート |

| 厚さ | 0.18~1.8mm |

| 幅 | 300~1400mm |

| 品質 | Virgin/Recycled |

| RPET content percentage | 30%-100% |

| PET Roll Diameter | ≤38 inch |

| 色 | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized |

| パフォーマンス | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| パッキング | 内側 +クラフトの外側 +パレット(紙のチューブの直径:76mm、厚さ:10mm) |

| 処理技術 | Thermoforming Vacuum Blister Forming, Die Cutting |

PET sheet type we offer

| PET sheet type | 幅(mm) | 厚さ(mm) | 色 | 抵抗値(ω) |

| Silicon-coated PET | 300-1400 | 0.18-1.8 | Transparent/Others | / |

| RPET sheet | Transparent/Others | / | ||

| GAG sheet | Transparent/Others | / | ||

| Anti-fog PET | Transparent/Others | / | ||

| High impact PET | Transparent/Others | / | ||

| PET lamination PE | Transparent/Others | / | ||

| PET sheet for electronic | ||||

| Conductive PET | 300-1400 | 0.18-1.8 | Transparent/Others | 104-106 |

| Semi-conductive PET | Transparent/Others | 106-109 | ||

| Anti-stactic PET | Transparent/Others | 109-1011 | ||

| Coated PET | Transparent/Others | 103-106 | ||

Main features

Food grade safety: Meets FDA, EU and other food contact standards, non-toxic and tasteless, safe and environmentally friendly.

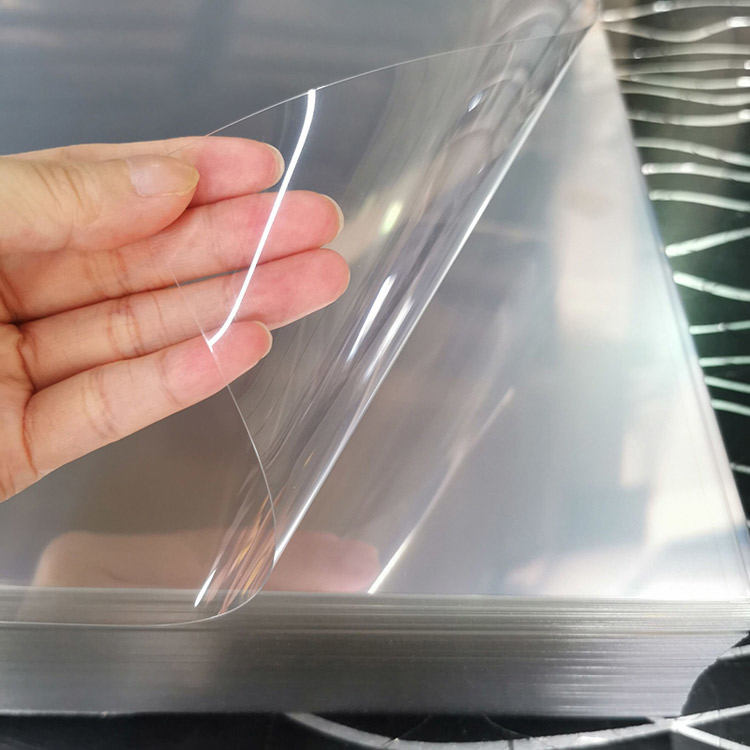

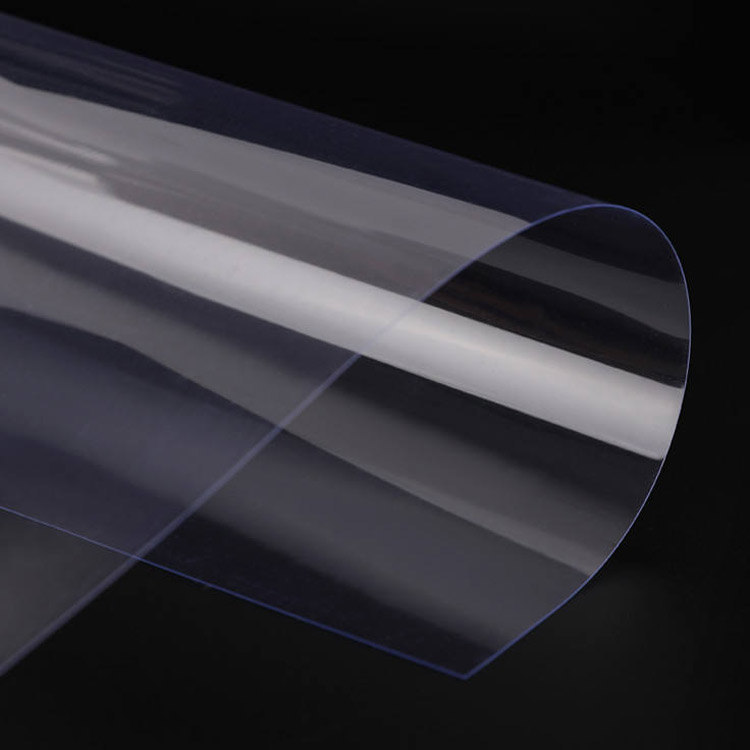

High transparency: With excellent optical properties and high light transmittance, the appearance of packaged food is clearly visible.

High strength and impact resistance: Compared with other plastic materials, PET has better toughness and impact resistance to ensure the stability of packaging.

Good temperature resistance: It can be used in the range of -40℃ to +70℃, suitable for refrigerated and room temperature food packaging.

Good chemical resistance: Resistant to oil, acid and alkali, not easy to react chemically with food, ensuring the original flavor of food.

環境にやさしくリサイクル可能: PET is a recyclable plastic, which conforms to the trend of green environmental protection and reduces environmental pollution.

advantages of food-grade PET plastic sheet rolls

(1) Excellent food safety performance

PET material itself does not contain harmful substances such as BPA and plasticizers, ensuring food health and safety.

After strict production process control, it meets international food safety standards, such as FDA (U.S. Food and Drug Administration), EU 10/2011 (EU Food Contact Materials Regulation), etc.

(2) High transparency and good display effect

The light transmittance of PET sheet can reach more than 90%, making packaged food more attractive and convenient for consumers to check product quality.

It can be used for high-end food packaging to increase product added value and market competitiveness.

(3) Excellent mechanical properties

It has good impact resistance and tensile strength, is not easy to break during transportation and storage, and ensures food safety.

Lightweight design effectively reduces the cost of packaging materials, while facilitating transportation and storage.

(4) Strong temperature resistance, suitable for a variety of food packaging needs

PET sheet can withstand refrigerated environments (-40℃) and is suitable for frozen food packaging, such as cold drinks, dairy products, frozen meat, etc.

It remains stable in high temperature environment (within 70℃) and can be used for room temperature food packaging, such as cakes, nuts, candies, etc.

(5) Easy to process and can undergo a variety of secondary treatments

It is suitable for processing technologies such as thermoforming, blistering, stamping, bending, etc., and can be used to make food packaging boxes and blister trays of different shapes.

The surface can be printed, coated, metallized, etc. to meet personalized packaging needs.

(6) Environmentally friendly and recyclable, in line with the trend of sustainable development

PET plastic is a 100% recyclable environmentally friendly material. After use, it can be remade into food packaging materials to reduce plastic pollution.

It complies with global green environmental protection policies and is favored by the market and consumers.

application of food-grade PET plastic sheet rolls

Due to its superior properties, food-grade PET sheet rolls are widely used in various food packaging fields, including but not limited to the following categories:

Production process of food-grade PET plastic sheet rolls

(1) Raw material preparation

Select food-grade PET resin particles to ensure that the material is pure and free of impurities.

Add antioxidants, UV inhibitors, etc. to improve the stability of PET sheets.

(2) Extrusion molding

PET resin particles are melted in a high-temperature extruder and extruded through a T-die to form a uniform sheet.

The sheet thickness is controlled within the range of 0.2mm-2mm and can be customized according to customer needs.

(3) Cooling and shaping

Quick cooling through cooling rollers ensures that the sheet surface is smooth and transparent.

Precisely control the thickness to improve the uniformity and physical properties of the sheet.

(4) Winding and packaging

Adopt high-precision automatic winding equipment to ensure that the PET sheet rolls are tight and neat, without wrinkles or bubbles.

Perform quality inspection to ensure that each roll of PET sheet meets food safety standards.

(5) Subsequent processing (optional)

The sheet can be printed, coated, laminated, metallized, etc. to enhance the decorativeness and functionality of the packaging.

Special functions such as anti-fog, anti-static, and antibacterial can be customized according to customer needs to meet different food packaging requirements.

Food-grade PET plastic sheet rolls have become an ideal choice for modern food packaging due to their excellent food safety, high transparency, good processing performance, temperature resistance and environmentally friendly recyclable characteristics. They are widely used in food trays, transparent packaging boxes, beverage bottles, cake boxes, etc., meeting the market demand for safe, beautiful and environmentally friendly packaging materials.

If you need high-quality food-grade PET plastic sheet rolls, please contact us for more information and free samples!

relate Products

a試合シェンガン

Shengan(Shanghai)New Materials Co.、Ltd - 信頼できるペットシートソリューションプロバイダー

2018年に上海に設立されたシェンガンは、高品質を専門としています ペットシート そして 熱酸化機械、エレクトロニクス、食品、化粧品、医療などのサービス業界。 120,000平方メートルの施設と高度な生産ラインにより、年間10,000トン以上を配信し、最高級の品質を確保してください ISO9001、GRS、およびSGS認定。

重要な製品

- ペットシート:apet、rpet(リサイクル)、esd antistic、gagシート。

- 機械:熱成形、カップ、ブリスターマシン。

- カスタムソリューション:あなたのニーズに合わせて調整されたOEMサービス。

グローバルリーチ

- にエクスポート 70か国以上 (アメリカ、ヨーロッパ、アジア、アフリカ)。

- 年間売上高 1,000万ドル、71%〜80%の輸出量。

卓越性へのコミットメント

- 顧客ファーストアプローチ:包括的なサポートと満足の保証。

- 持続可能な慣行:環境に優しい素材とGRS認定生産。