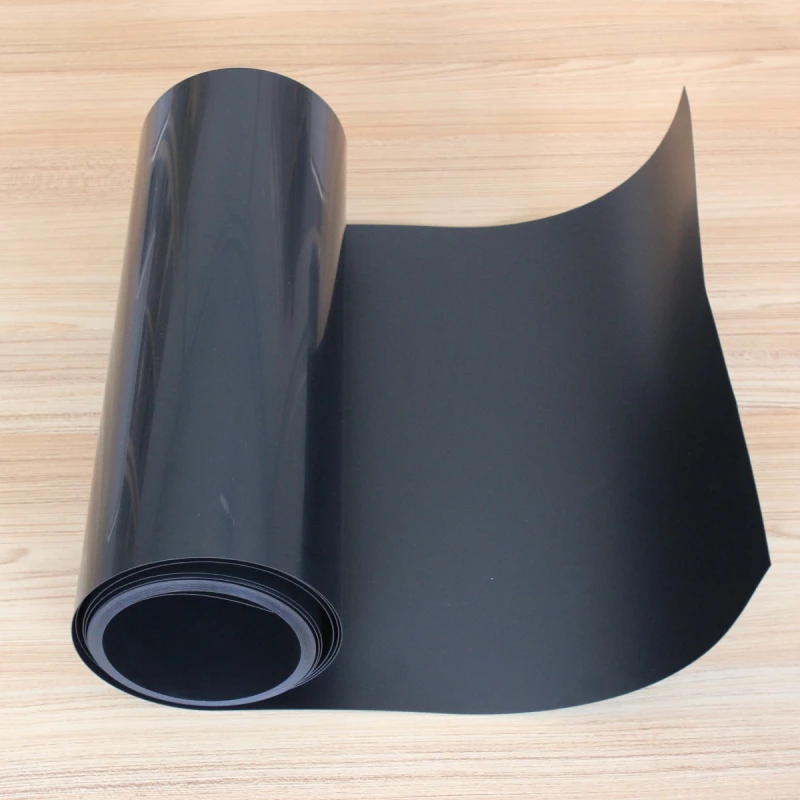

PP Plastic Sheet Roll

Introduction to PP Plastic Sheet

PP (polypropylene) plastic sheet is a sheet material made of polypropylene resin through an extrusion molding process, with excellent chemical resistance, mechanical properties and environmental protection characteristics. PP sheets can be modified according to different needs, such as enhancing toughness, improving transparency or adding UV resistance, making them suitable for various industrial and consumer applications.

Specifications of PP sheet

| Product Name | PP Sheet, Polypropylene Sheet, Rigid PP Film. |

| Composite Type | PP/EVOH/PE, PP/EVOH/PP, PP/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.2~2.0mm |

| Width | 300~850mm |

| PP Roll Diameter | ≤38 inch |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Quality | 100% virgin |

| Color | Clear, Natural, Black, White, Color, Customized according to needs. |

| Surface Treatment | Matte, Glossy. |

| Performance | ESD: Anti-static, Conductive, Static dissipative. Corona; Printing; Coating; Waterproof; etc |

| Processing technology | Thermoforming Vacuum Blister Forming, Die cutting. |

| Hardness | Rigid / Semi-rigid |

Types of PP sheets we offer

| PP sheet type | Width (mm) | Thickness (mm) | Color | Resistance value (Ω) |

| PP normal sheet | 300-850 | 0.2-2.0 | Any/Customized | / |

| PP sheet for frozen tray | Any/Customized | / | ||

| PP sheet for cooked food tray | Any/Customized | / | ||

| PP/PE | Any/Customized | / | ||

| PP/EVOH/PP | Any/Customized | / | ||

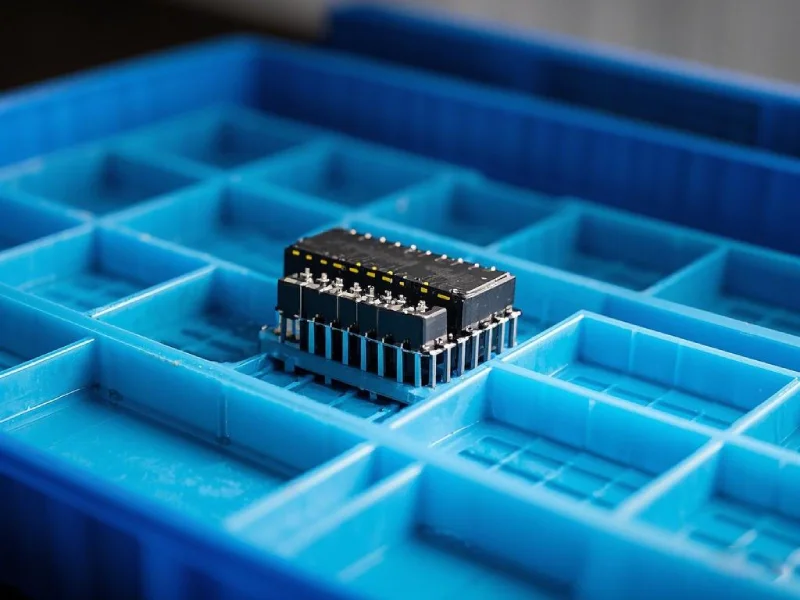

| PP conductive sheet | Any/Customized | 104-106 |

Main features

Excellent chemical resistance: PP sheets are resistant to erosion by chemicals such as acids, alkalis, and salts, and are suitable for packaging and industrial uses.

Excellent mechanical properties: It has good toughness, impact resistance and tensile strength, and can withstand certain external forces without being easily broken.

Environmentally friendly and recyclable: PP is a recyclable plastic material that meets environmental protection requirements and reduces environmental pollution.

Good thermoformability: PP sheets are suitable for vacuum forming, bending, hot pressing and other processes, and are easy to process into products of various shapes.

High and low temperature resistance: PP sheets have good heat resistance, and some modified PP materials can withstand high temperatures above 100°C, while still maintaining a certain toughness in low temperature environments.

Low density and lightweight: PP sheets are lighter than other plastic sheets (such as PVC and PET), which helps reduce product weight and transportation costs.

Advantages of PP plastic sheet rolls

(1) Food grade safety: PP plastic sheets meet food contact safety standards, are non-toxic and odorless, and are suitable for food packaging.

(2) Strong durability: Impact and tear resistance, suitable for multiple-use packaging and industrial purposes.

(3) Low cost and high efficiency: Compared with other engineering plastics, PP sheets are moderately priced and have good processing performance.

(4) Wide compatibility: Can be co-extruded or laminated with other materials (such as PE, EVA, etc.) to enhance performance.

Application of PP plastic sheet rolls

🔹 Food packaging: widely used in frozen food packaging, takeaway boxes, microwave heating containers, etc.

🔹 Electronic product packaging: used for anti-static trays, electronic component protection boxes.

🔹 Medical industry: used for disposable medical trays, test tube racks, drug packaging, etc.

🔹 Stationery and daily necessities: used for file boxes, storage boxes, plastic cups, etc.

FAQS

Riñonalelate Products

ASHENGAN

Shengan (Shanghai) New Materials Co., Ltd - Su proveedor de soluciones de hoja de mascotas de confianza

Establecido en 2018 en Shanghai, Shengan se especializa en alta calidad Sábanas para mascotas y maquinaria termoformadora, sirviendo industrias como electrónica, alimentos, cosméticos y médicos. Con una instalación de 120,000 metros cuadrados y líneas de producción avanzadas, entregamos más de 10,000 toneladas métricas anualmente, asegurando una calidad de primer nivel con Certificaciones ISO9001, GRS y SGS.

Ofrendas clave

- Sábanas para mascotas: APET, RPET (reciclado), ESD Antistático, láminas de mordaza.

- Maquinaria: Máquinas de termoformado, taza y ampolla.

- Soluciones personalizadas: Servicios OEM adaptados a sus necesidades.

Alcance global

- Exportar a Más de 70 países (América, Europa, Asia, África).

- Ventas anuales superiores $ 10 millones, con 71% -80% de volumen de exportación.

Compromiso con la excelencia

- Enfoque del primer cliente: Garantía integral de apoyo y satisfacción.

- Prácticas sostenibles: Materiales ecológicos y producción certificada por GRS.