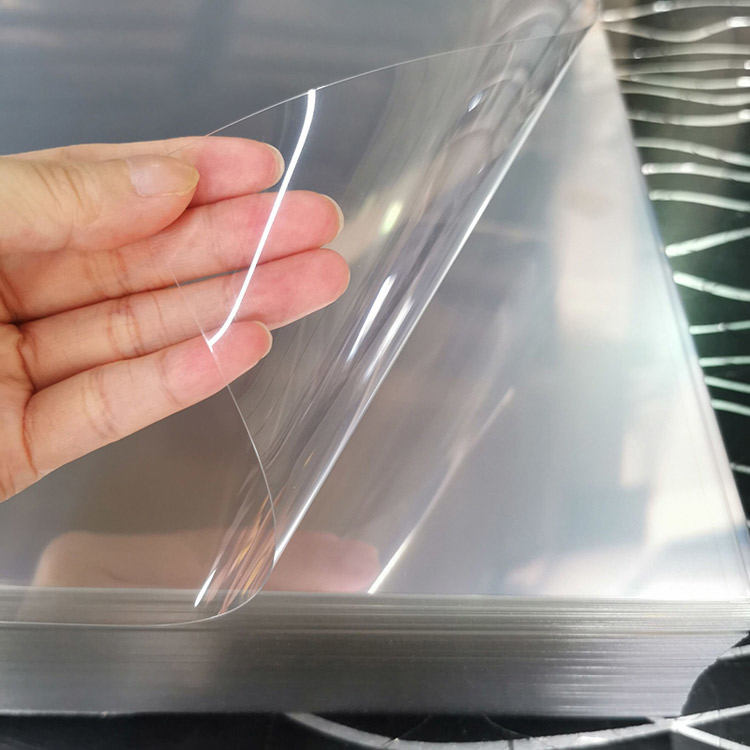

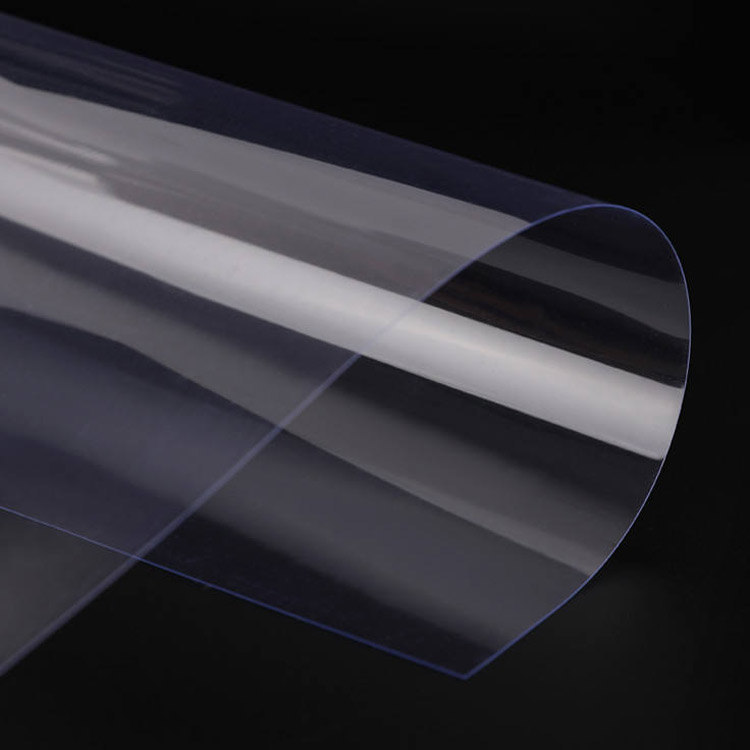

PET sheet for vacuum forming

PET Sheet offers excellent light transmittance and mechanical strength, high resistance to oxygen and water vapor, customized cutting and special functional additives, high-end customization. ABA three-layer co-extrusion structure, in line with EFSA and FDA food safety certification, widely used in food and beverage packaging industry

Specifications of PET sheet roll

| Product Category | APET, GAG, RPET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~1.8mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| RPET content percentage | 30%-100% |

| PET Roll Diameter | ≤38 inch |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, Waterproof, Oil-proof, Anti-UV, etc. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting |

| Properties | UNIT | METHOD | Virgin PET | Pre-consumer/Post Recycled PET | |||

|---|---|---|---|---|---|---|---|

| Data | (ASTM) | 100% PET | RPET 25% | RPET 30% | |||

| Thickness Tolerance | %/mm | / | ±5% | ±5% | ±5% | ||

| Thickness Range | mm | / | 0.18 – 1.8 | 0.18 – 1.8 | 0.12 – 1.8 | ||

| Width Tolerance | mm | / | ±2mm | ±2mm | ±2mm | ||

| Width Range | mm | / | 300 – 1400 | 300 – 1400 | 300 – 1400 | ||

| Weight Tolerance | % | / | ±3% | ±3% | ±3% | ||

Main features

- Excellent ffavour barrier properries

- Easy thermoforming characteristics

- Excellent impact resistance

- High transparency and gloss

- ABA Multi-layer

- Tighter thickness tolerances and more precise

- Fully automatic PLC production equipment, with PET sheet stable perrormance

- On-line detection system reduces the failure rate and stabilizes the quality

Advantages of PET plastic sheet rolls

(1) Excellent food safety performance

PET material itself does not contain harmful substances such as BPA and plasticizers, ensuring food health and safety.

After strict production process control, it meets international food safety standards, such as FDA (U.S. Food and Drug Administration), EU 10/2011 (EU Food Contact Materials Regulation), etc.

(2) High transparency and good display effect

The light transmittance of PET sheet can reach more than 90%, making packaged food more attractive and convenient for consumers to check product quality.

It can be used for high-end food packaging to increase product added value and market competitiveness.

(3) Excellent mechanical properties

It has good impact resistance and tensile strength, is not easy to break during transportation and storage, and ensures food safety.

Lightweight design effectively reduces the cost of packaging materials, while facilitating transportation and storage.

(4) Strong temperature resistance, suitable for a variety of food packaging needs

PET sheet can withstand refrigerated environments (-40℃) and is suitable for frozen food packaging, such as cold drinks, dairy products, frozen meat, etc.

It remains stable in high temperature environment (within 70℃) and can be used for room temperature food packaging, such as cakes, nuts, candies, etc.

(5) Easy to process and can undergo a variety of secondary treatments

It is suitable for processing technologies such as thermoforming, blistering, stamping, bending, etc., and can be used to make food packaging boxes and blister trays of different shapes.

The surface can be printed, coated, metallized, etc. to meet personalized packaging needs.

(6) Environmentally friendly and recyclable, in line with the trend of sustainable development

PET plastic is a 100% recyclable environmentally friendly material. After use, it can be remade into food packaging materials to reduce plastic pollution.

It complies with global green environmental protection policies and is favored by the market and consumers.

PET sheet type we offer

| PET sheet type | Width (mm) | Thickness (mm) | Color | Resistance value (Ω) |

| Silicon-coated PET | 300-1400 | 0.18-1.8 | Transparent/Others | / |

| RPET sheet | Transparent/Others | / | ||

| GAG sheet | Transparent/Others | / | ||

| Anti-fog PET | Transparent/Others | / | ||

| High impact PET | Transparent/Others | / | ||

| PET lamination PE | Transparent/Others | / | ||

| PET sheet for electronic | ||||

| Conductive PET | 300-1400 | 0.18-1.8 | Transparent/Others | 104-106 |

| Semi-conductive PET | Transparent/Others | 106-109 | ||

| Anti-stactic PET | Transparent/Others | 109-1011 | ||

| Coated PET | Transparent/Others | 103-106 | ||

ASHENGAN

Shengan (Shanghai) New Materials Co., Ltd - Su proveedor de soluciones de hoja de mascotas de confianza

Establecido en 2018 en Shanghai, Shengan se especializa en alta calidad Sábanas para mascotas y maquinaria termoformadora, sirviendo industrias como electrónica, alimentos, cosméticos y médicos. Con una instalación de 120,000 metros cuadrados y líneas de producción avanzadas, entregamos más de 10,000 toneladas métricas anualmente, asegurando una calidad de primer nivel con Certificaciones ISO9001, GRS y SGS.

Ofrendas clave

- Sábanas para mascotas: APET, RPET (reciclado), ESD Antistático, láminas de mordaza.

- Maquinaria: Máquinas de termoformado, taza y ampolla.

- Soluciones personalizadas: Servicios OEM adaptados a sus necesidades.

Alcance global

- Exportar a Más de 70 países (América, Europa, Asia, África).

- Ventas anuales superiores $ 10 millones, con 71% -80% de volumen de exportación.

Compromiso con la excelencia

- Enfoque del primer cliente: Garantía integral de apoyo y satisfacción.

- Prácticas sostenibles: Materiales ecológicos y producción certificada por GRS.