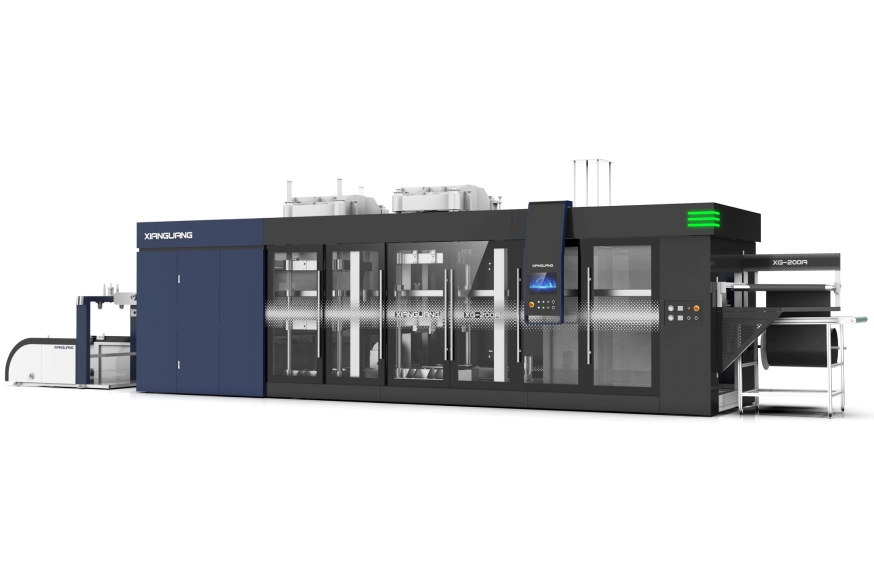

完全自动大型四站正和负压热成型机

XG-A-3-3 High-Efficiency Programmable Plastic Pneumatic Thermoforming Machine, suitable for the forming of various plastic sheets such as HIPS, PLA, BOPS, PS, PP, PVC, PET, ABS, etc.

乙quipment Overview

Feature:

这 XG-A-3-3 High-Efficiency Programmable Plastic Pneumatic Thermoforming Machine applies advanced plastic sheet forming technology and integrates machine, electricity, and air systems into one design. It utilizes a microcomputer and industrial control programmable PLC for operation, with an HMI (Human-Machine Interface) system.

The equipment includes a square tunnel-type imported radiation heater, capable of forming both male and female molds, and a laser blade cutting system. The process flow includes heating, forming, punching, cutting, stacking, and counting, which are all part of a multi-station production line.

The production line operates synchronously, employing the latest forming technology to reduce labor, prevent secondary contamination, save materials, improve product quality and compliance, significantly increase production efficiency, and enhance ease of operation, reliability, and functionality. It is an automated production line for sheet thermoforming and automatic punching and cutting of products.

Application:

适用于HIPS、PLA、BOPS、PS、PP、PVC、PET、ABS等各种塑料片材成型。该机可生产高透明、高拉伸、浅拉伸、圆形、方形、异形、双向拉伸、翻边等产品。其中包括盒子、托盘、碗、盖、工业包装、电子托盘、食品包装、文具包装、化妆品包装和其他塑料包装产品。

t技术参数

| Term Description | Technical Parameters |

|---|---|

| Forming Mold Area | 850mm × 750mm |

| Forming Mold Area | 350mm × 360mm |

| 板材宽度 | 800mm |

| 板材宽度 | 390mm |

| 成型高度 | Male mold: 130mm, Female mold: 120mm |

| Material Thickness | 0.15—2.0mm |

| Forming Speed | 4-45 cycles/min (depending on product) |

| Sheet Roll Diameter | 1000mm (500kg) |

| Forming Mold Stroke | Upper: 150mm, Lower: 150mm |

| Cutting Mold Stroke | Upper: 250mm, Lower: 150mm |

| Punching Mold Stroke | 50mm |

| Cutting Mold Stroke | 50mm |

| Cutting Force | 80 tons (for knife length ≤ 10 meters) |

| Stacking System | 2.0kw and 1.5kw Delta servo motors from Taiwan, with stacking options for high products (<130mm) with hanging points to stack down, and low products (<80mm) with robotic arm either inside or outside the mold, 3 working modes available. |

| Forming Station | Lower servo motor cam lever linkage with hard tooth gear reducer drive, upper servo motor cam lever linkage with hard tooth gear reducer drive. |

| Cutting Station | Lower servo motor cam lever linkage with hard tooth gear reducer drive, upper servo motor cam lever linkage with hard tooth gear reducer direct punching. |

| Cooling Method | High-pressure, large flow circulation water cooling for molds |

| Client Air Source (external) | Air supply ≥ 5.5m³/min, air pressure 0.6~0.8 MPa |

| 电源 | 380V/50HZ (Three-phase five-wire) |

| Total Power | Installed power: 138KW (Normal operating power approx. 30-60KW) |

| Total Weight (Reference) | 15.5T |

| 方面 | 14500 × 2000 × 3000mm (for reference) |

| Mold Temperature Monitoring | Temperature gauge to display actual mold temperature, ensuring product quality and production efficiency in real-time. |

| Value Positioning | A. Integrated forming, cutting, and stacking system for smoother processing and lower energy consumption. B. Forming and cutting stations use sturdy mechanical structures with cam levers and roller bearings to ensure perfect forming and cutting. |

| Forming Method | Positive and negative pressure hot press thermoforming |

| Cutting Station | Expandable mold table design, easy, safe, and quick mold replacement with laser cutting tool. |

乙quipment process flow

Sheet supply → Sheet transport → First heating stage → Second heating stage → Forming and cooling → Cutting → Separation and stacking → Waste material rewinding system

Note: The production line consists of three workstations. The operation mode can switch between manual and automatic, with manual operation facilitating sample extraction and parameter setting control.

乙quipment technical description

A. Forming Equipment Structure:

The forming equipment consists of the main structural frame, positive and negative pressure forming system, temperature control system, vacuum system, heating system, pneumatic control system, electrical and PLC control system, punching system, product decomposing robotic arm stacking, and automatic waste material rewinding system.

B. Main Body Structure:

The main body is assembled from square tubes and channel steels, welded together to form the structure that supports heating, mold forming, mold punching, mold cutting, and auxiliary devices. The steel frame structure is designed following Structural Process Design, ensuring all involved parts meet the following standards: high-quality material selection, blank production methods, machining, heat treatment, part assembly, machine operation, and maintenance processes. This guarantees sufficient strength and rigidity for movable devices that transmit and convert motion and force. All metal surfaces are treated with anti-rust coating and base layer anti-corrosion paint. Standard components are used in the structure for easy maintenance and future part replacement.

C. Mold Table Structure:

The bottom servo motor cam lever linkage drives the hard tooth gear reducer, and the top servo motor cam lever linkage drives the same system.

D. Electrical and PLC Control System / Safety Features

电气控制系统:

The electrical control system uses a PLC integrated module, with an industrial touch display as the HMI (Human-Machine Interface) featuring a Chinese interface. The machine includes button controls for operation and settings, as well as the ability to modify all process parameters, making it easy to operate and maintain.

Working Mode:

The machine operates in both manual and automatic modes. All settings and operations are handled via the touch display. After the operator places the material, pressing the “automatic” button starts the full process of thermoforming until the material in the hopper is processed. Manual mode is primarily used for mold changing or sample control.

Safety Measures:

The system includes multiple protection measures, with interlocking and closed-loop control to prevent collisions between moving parts.

The safety door is designed for manual locking and opening, and includes an integrated safety light curtain to enhance device safety, ensuring personnel and property safety.

Electrical Cabinet:

The electrical cabinet contains protective circuits, including overcurrent, overvoltage, undervoltage, short-circuit, and overload protection. The heating elements have fuse protection. For safety concerns that may pose a hazard to the system or parts, warning labels or notes are included. The control cabinet has 10% reserved space for future expansion of additional forming functions. The cabinet is equipped with filters and protective cooling fans.

Cables and Wiring:

All non-moving cables and wiring outside of power boxes are hidden in cable ducts, making it easier to access for repairs. If this is not possible, flexible hose fixation is used.

Emergency Stop Function:

Multiple “emergency stop” buttons are installed at the front, middle, and rear of the equipment. The emergency stop button immediately cuts off the power supply, ensuring no dangerous situations arise during emergency stops.

A关于SHENGAN

盛安(上海)新材料有限公司 – 您的塑料包装解决方案合作伙伴

盛安于2018年在中国上海成立,是一家致力于为塑料包装行业提供一体化解决方案的全球领先合作伙伴。从高性能材料到成品和机械,我们为全球企业提供支持。

我们的综合解决方案

- 高级塑料板材: 我们专注于全系列的热塑性板材,包括 APET、RPET(再生 PET)、PETG、PP、PS、GAG 和 ESD 安全 材料,满足多样化和高要求的应用。

- 食品级成品: 我们超越原材料来制造高质量、定制设计的包装,例如 食品级塑料托盘、一次性杯子 & 盖子和定制热成型泡罩包装。

- 可靠的机械 & 设备: 为了完成您的生产周期,我们提供并支持高效 PET热成型杯机和吸塑包装机。

质量认证,全球标准

我们的承诺得到了国际认证的验证,例如 ISO 9001、FSSC、FDA 和 GRS,确保我们的产品满足最严格的质量、食品安全和可持续性要求。

为何与盛安合作?

- 端到端集成: 我们通过提供从材料到机械的一切来简化您的供应链,确保一致性、效率和成本效益。

- 对质量的承诺 & 安全: 我们的生产得到严格的国际认证的支持,包括 ISO 9001、ISO 14001、FSSC、FDA、HACCP 和 GRS(针对 RPET),保证产品符合全球最高标准。

- 久经考验的卓越制造: 在上海战略生产基地的支持下,我们有能力为全球客户提供可扩展、可靠的解决方案和无缝供应链管理。