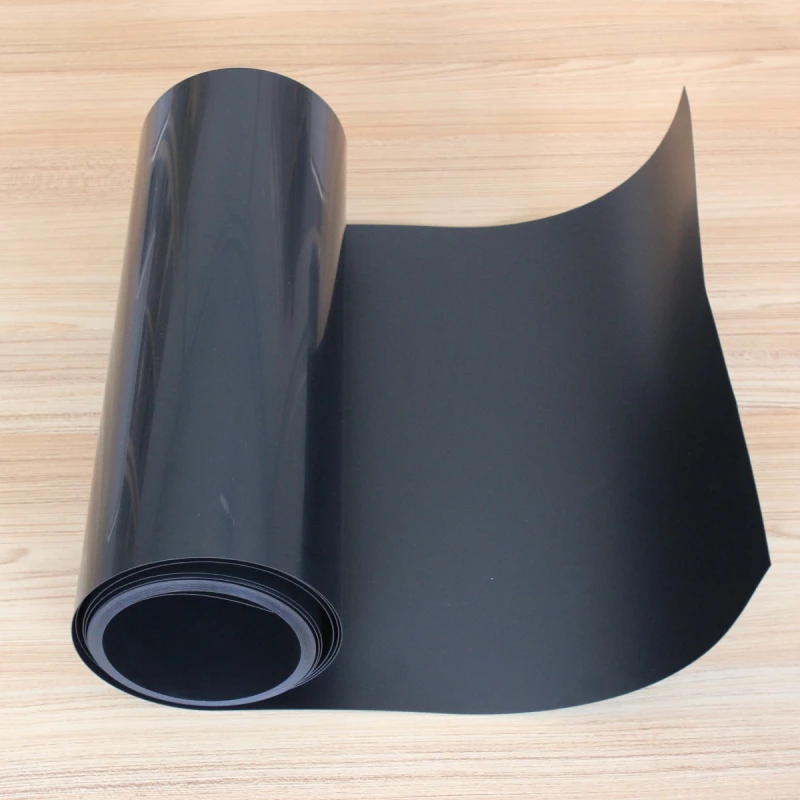

Проводящий пластиковый лист бедра

яЗнакомство с проводящим пластиковым листом HIPS

Проводящий пластиковый лист HIPS — это термопластичный лист, в который добавлены проводящие наполнители (такие как проводящая сажа, углеродные нанотрубки, металлические волокна и т. д.) или используется специальная обработка покрытия на основе HIPS (ударопрочный полистирол), чтобы придать ему долговечные и стабильные проводящие свойства. Он не только сохраняет первоначальную высокую ударопрочность и превосходные характеристики формования и обработки HIPS, но также придает материалу антистатические свойства, которые широко используются в электронике, медицине, промышленности и других областях.

СТехнические характеристики рулона листов HIPS

| Название продукта | PS лист; PS Ролл; Лист полистирола; Жесткая PS-пленка. |

| Категория продукта | Пластик HIPS, Пластик GPPS |

| Композитный тип | ПС/ЭВС/ПС, ПС/ЭВС/ПЭ, ПП/ПЭ и т. д. |

| Форма | Рулон/Лист |

| Толщина | 0.3~2,0 мм |

| Ширина | 300~850 мм |

| Упаковка | Полиэтиленовая пленка внутри + крафт снаружи + поддон (диаметр бумажной трубки: 76 мм, толщина: 10 мм) |

| Качество | 100% девственница |

| Цвет | Прозрачный, натуральный, черный, белый, цветной, по индивидуальному заказу в соответствии с потребностями. |

| Обработка поверхности | Матовый, глянцевый, флокированный. |

| Производительность | ESD: антистатический, проводящий, рассеивающий статическое электричество. Корона; Печать; Покрытие; ЭВОН; Водонепроницаемый; и т. д. |

| Технология обработки | Термоформование, вакуумное формование, блистерная обработка, высечка. |

| Твердость | Жесткий/Полужесткий |

Твиды листов HIPS, которые мы предлагаем

| Тип листа HIPS | Ширина (мм) | Толщина (мм) | Цвет | Значение сопротивления (Ом) |

| HIPS обычный лист | 300-850 | 0.2-2,0 | Любой/индивидуальный | / |

| Ударопрочные HIPS | Любой/индивидуальный | / | ||

| HIPS черный токопроводящий | Черный | 104-106 | ||

| HIPS черный полупроводниковый | Черный | 106-109 | ||

| HIPS черный объемный токопроводящий | Черный | 104-106 | ||

| Полимерный лист HIPS | Любой/индивидуальный | 108 | ||

| Антистатический лист HIPS | Любой/индивидуальный | 109-1011 | ||

| Лист с покрытием HIPS | Любой/индивидуальный | 103-109 |

ВХарактеристики проводящих пластиковых листов HIPS

Стабильная проводимость: Поверхностное сопротивление можно контролировать в диапазоне 10³-10⁶Ом, что эффективно предотвращает накопление и выброс статического электричества и обеспечивает безопасность электронных компонентов.

Отличная ударная вязкость: Более ударопрочный, чем обычные материалы PS, его нелегко сломать, он защищает электронные продукты в упаковке.

Хорошая адаптируемость к обработке: Его можно обрабатывать вакуумным формованием, горячим прессованием, штамповкой, гибкой и другими методами обработки, подходящими для различных требований к продукции.

Химическая коррозионная стойкость: Он обладает хорошей устойчивостью к большинству химических растворителей, кислот и щелочей и подходит для различных промышленных сред.

Экологичность и возможность вторичной переработки: Его можно использовать повторно, он соответствует экологическим нормам и снижает производственные затраты предприятий.

АПреимущества проводящего пластикового листа HIPS

Сильная способность электростатической защиты, защита чувствительных продуктов

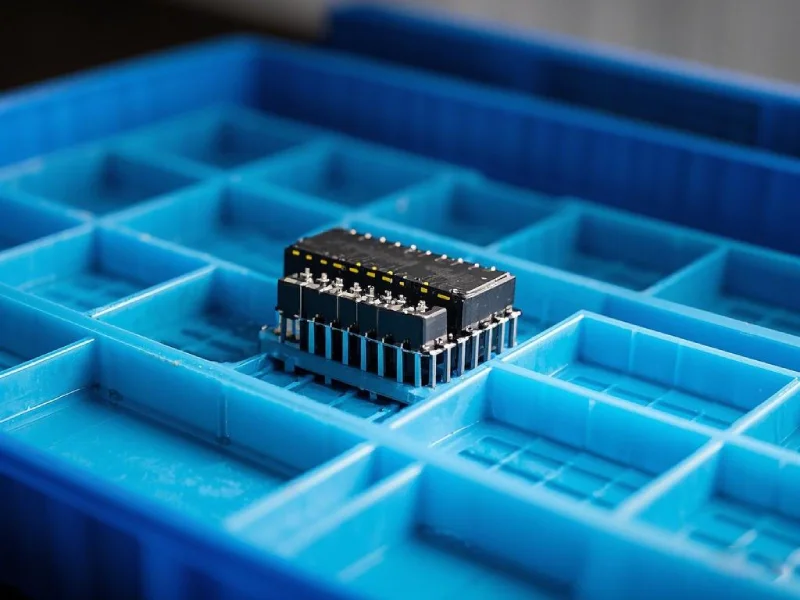

Проводящий лист HIPS может эффективно устранять статическое электричество, предотвращать повреждение электронных компонентов, микросхем, печатных плат и других чувствительных продуктов из-за накопления статического электричества, а также повышать уровень квалификации продукта.

Экономичен и эффективен, заменяет металл и другие антистатические материалы.

По сравнению с проводящими металлическими материалами проводящий лист HIPS легче, дешевле и имеет хорошую технологичность, что больше подходит для крупномасштабного производства.

Высокая механическая прочность, ударопрочность, нелегко сломать

Материал прочен и долговечен, выдерживает внешние воздействия, обеспечивает надежную защиту продукции при транспортировке и хранении.

Подходит для различных методов обработки, хороший эффект формования.

Его можно обрабатывать вакуумным формованием, гибкой, штамповкой и другими методами. Поверхность гладкая и однородная, а размер стабилен после формования, что позволяет удовлетворить различные требования применения.

АПрименение рулонов пластиковых листов HIPS

📌 Электронная и полупроводниковая промышленность: антистатическая упаковка: лоток для микросхем, держатель микросхем для предотвращения статического повреждения чувствительных компонентов.

📌Медицинская промышленность: лоток для хирургических инструментов: антистатический дизайн, позволяющий избежать адсорбции пыли и обеспечить стерильную среду.

📌Промышленное производство: хранение прецизионных механических деталей, защита при транспортировке изделий, чувствительных к электростатическому заряду.

📌 Автомобильная промышленность: лоток для упаковки электронных компонентов.

Виндуктивный процесс проводящего пластикового листа HIPS

Модификация проводящего наполнения

Добавьте к подложке HIPS проводящую сажу, металлическое волокно или углеродные нанотрубки, чтобы сделать материал проводящим в целом. Этот метод гарантирует, что материал обладает проводящими свойствами как внутри, так и на поверхности, а проводящий эффект является длительным и стабильным.

Проводимость поверхностного покрытия

Распылите проводящее покрытие на поверхность листа HIPS, чтобы сформировать проводящую защитную пленку. Этот метод подходит для изделий с особыми требованиями к поверхностному сопротивлению.

Процесс смешивания и компаундирования

HIPS смешивается с проводящими полимерными материалами, чтобы придать материалу антистатические свойства, сохраняя при этом технологические преимущества HIPS.

Технология композитной ламинации

На поверхность листа HIPS крепится проводящая пленка для улучшения антистатической способности при обеспечении механической прочности и долговечности материала.

ФонАКС

Ведущийв восторге от продуктов

АБой Шенган

Компания ShengAn (Шанхай) New Materials Co., Ltd – Ваш партнер в области решений для пластиковой упаковки

Компания ShengAn, основанная в 2018 году в Шанхае, Китай, является ведущим мировым партнером, предоставляющим комплексные решения для индустрии пластиковой упаковки. От высокоэффективных материалов до готовой продукции и оборудования, мы расширяем возможности бизнеса по всему миру.

Наши комплексные решения

- Усовершенствованные пластиковые листы: Мы специализируемся на полном спектре термопластических листов, в том числе APET, RPET (переработанный ПЭТ), PETG, PP, PS, GAG и ESD-безопасность. материалы, предназначенные для разнообразных и требовательных применений.

- Готовая пищевая продукция: Мы не ограничиваемся сырьем и производим высококачественную упаковку по индивидуальному заказу, такую как пищевые пластиковые лотки, одноразовые стаканчики & крышки и термоформованная блистерная упаковка по индивидуальному заказу.Полем

- Надежное оборудование & Оборудование: Для завершения вашего производственного цикла мы поставляем и поддерживаем эффективные Машины для термоформования ПЭТ-стаканов и блистерные упаковочные машиныПолем

Сертифицированное качество, мировые стандарты

Наша приверженность подтверждена международными сертификатами, такими как ISO 9001, FSSC, FDA и GRS., гарантируя, что наша продукция соответствует самым строгим требованиям к качеству, безопасности пищевых продуктов и устойчивому развитию.

Почему стоит сотрудничать с ShengAn?

- Сквозная интеграция: Мы оптимизируем вашу цепочку поставок, предлагая все, от материалов до оборудования, обеспечивая согласованность, эффективность и экономичность.

- Приверженность качеству & Безопасность: Наша продукция подтверждена строгими международными сертификатами, в том числе ISO 9001, ISO 14001, FSSC, FDA, HACCP и GRS (для RPET), гарантируя, что продукция соответствует самым высоким мировым стандартам.

- Проверенное производственное совершенство: Благодаря нашим стратегическим производственным базам в Шанхае мы обладаем способностью предоставлять масштабируемые, надежные решения и бесперебойное управление цепочками поставок для клиентов по всему миру.