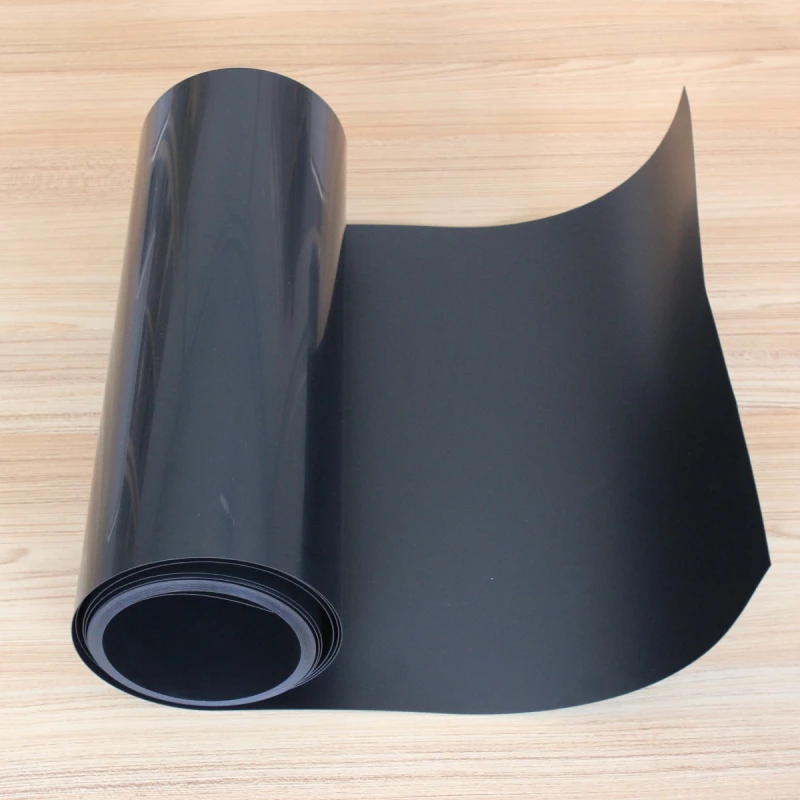

PP Conductive Sheet Roll

Antistatic materials are essential in modern industrial manufacturing and electronic packaging. Conductive PP plastic sheet roll is a thermoplastic material with excellent conductive properties and antistatic effects. The resistance value is between 10⁴-10⁶ Ω, which can effectively release static electricity and protect sensitive electronic components and high-precision instruments from static damage.

What is conductive PP plastic sheet?

Conductive PP (polypropylene) plastic sheet is based on PP resin. By adding conductive carbon powder, carbon nanotubes or conductive masterbatch, it has stable conductivity and excellent physical and mechanical properties. Its main features are light weight, strong chemical resistance, high mechanical strength, environmental protection and recyclability. It is particularly suitable for electronics, medical and industrial packaging.

Specifications of PP sheet

| Product Name | Conductive PP sheet roll |

| Resistance Value (Ω) | 10^4-10^6 |

| Shape | Roll/Sheet |

| Thickness | 0.2~2.0mm |

| Width | 300~850mm |

| PP Roll Diameter | ≤38 inch |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Quality | 100% virgin |

| Color | Clear, Natural, Black, White, Color, Customized according to needs. |

| Surface Treatment | Matte, Glossy. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die cutting. |

| Hardness | Rigid / Semi-rigid |

Types of PP sheets we offer

| PP sheet type | Width (mm) | Thickness (mm) | Color | Resistance value (Ω) |

| PP normal sheet | 300-850 | 0.2-2.0 | Any/Customized | / |

| PP sheet for frozen tray | Any/Customized | / | ||

| PP sheet for cooked food tray | Any/Customized | / | ||

| PP/PE | Any/Customized | / | ||

| PP/EVOH/PP | Any/Customized | / | ||

| PP conductive sheet | Any/Customized | 104-106 |

Characteristics of conductive PP plastic sheet

Excellent conductive performance: The resistance value ranges from 10⁴-10⁶ Ω, which can effectively release static electricity and prevent damage to electronic components.

Lightweight and high strength: Compared with traditional conductive plastic materials, PP sheets are lighter while maintaining high impact strength and folding resistance.

Strong chemical resistance: Acid and alkali resistance, solvent resistance, suitable for all kinds of harsh environments.

Environmentally friendly and recyclable: PP material is non-toxic and harmless, recyclable, and meets the requirements of sustainable development.

Good thermoforming: Suitable for vacuum forming, stamping, bending and other processing methods, can be used to customize various packaging shapes.

Advantages of conductive PP plastic sheet

🔹 More efficient static discharge: More conductive than ordinary anti-static PP, suitable for more stringent static control requirements.

🔹 Longer service life: Compared with surface coating anti-static materials, the conductive properties of conductive PP are evenly distributed and will not fail due to wear.

🔹 Wider application range: It can be used in multiple industries such as electronics, automobiles, and medical care to meet the needs of various scenarios.

🔹 More cost-effective: Compared with conductive PS, conductive ABS and other materials, PP materials have lower costs and excellent performance and processing adaptability.

Application of PP plastic sheet rolls

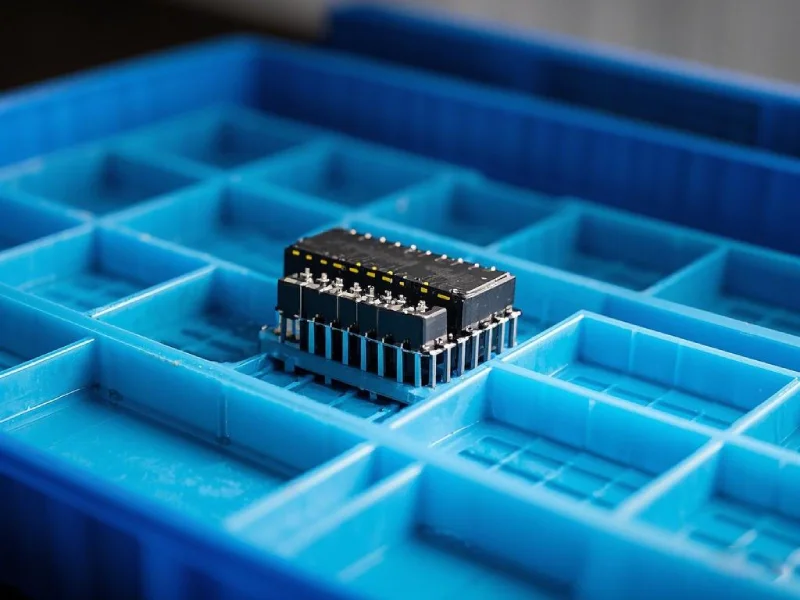

📌 Electronic packaging: IC tray, PCB board transport packaging, electronic component buffer packaging

📌 Medical industry: biopharmaceutical equipment packaging, anti-static medical supplies packaging

📌 Automobile industry: transportation and storage of automotive electronic accessories

📌 Logistics and transportation: anti-static turnover boxes, conductive trays, partitions, etc.

📌 Industrial manufacturing: clean room anti-static partitions, workbench gaskets, etc.

FAQS

Relate Products

About SHENGAN

ShengAn (Shanghai) New Materials Co., Ltd – Your Partner in Plastic Packaging Solutions

Established in 2018 in Shanghai, China, ShengAn is a leading global partner dedicated to providing integrated solutions for the plastic packaging industry. From high-performance materials to finished products and machinery, we empower businesses worldwide.

Our Comprehensive Solutions

- Advanced Plastic Sheets: We specialize in a full range of thermoplastic sheets, including APET, RPET (Recycled PET), PETG, PP, PS, GAG, and ESD-safe materials, catering to diverse and demanding applications.

- Food-Grade Finished Products: We go beyond raw materials to manufacture high-quality, custom-engineered packaging, such as food-grade plastic trays, disposable cups & lids, and custom thermoformed blister packaging.

- Reliable Machinery & Equipment: To complete your production cycle, we supply and support efficient PET thermoforming cup machines and blister packaging machines.

Certified Quality, Global Standards

Our commitment is validated by international certifications like ISO 9001, FSSC, FDA, and GRS, ensuring that our products meet the strictest requirements for quality, food safety, and sustainability.

Why Partner with ShengAn?

- End-to-End Integration: We streamline your supply chain by offering everything from materials to machinery, ensuring consistency, efficiency, and cost-effectiveness.

- Commitment to Quality & Safety: Our production is backed by stringent international certifications, including ISO 9001, ISO 14001, FSSC, FDA, HACCP, and GRS (for RPET), guaranteeing products that meet the highest global standards.

- Proven Manufacturing Excellence: Supported by our strategic production bases in Shanghai, we possess the capability to deliver scalable, reliable solutions and seamless supply chain management for clients across the globe.