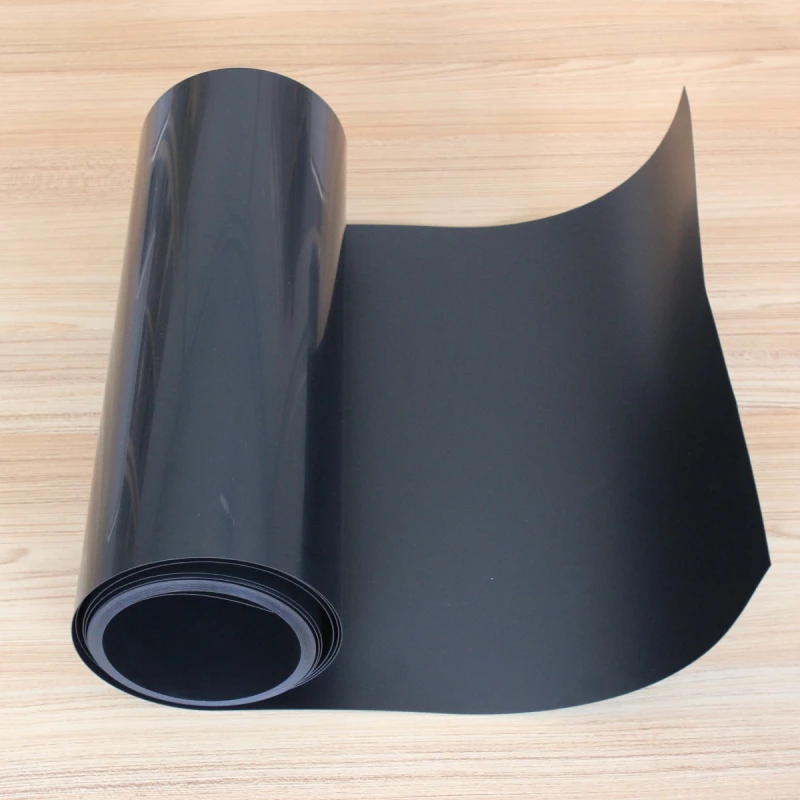

股関節導電性プラスチックシート

私股関節への導電性プラスチックシートへの導入

HIPS導電性プラスチックシートは、導電性フィラー(導電性カーボンブラック、カーボンナノチューブ、金属繊維など)を追加する熱可塑性シートであるか、股関節(高衝撃ポリスチレン)に基づいて特別なコーティング処理を使用して、長持ちして安定した伝導特性を備えています。元の高い衝撃抵抗と股関節の優れた成形と加工性能を維持するだけでなく、電子機器、医療、産業、その他の分野で広く使用されている物質的な反静的能力も提供します。

sヒップシートロールの特異的

| 製品名 | PSシート; PSロール;ポリスチレンシート;厳格なPSフィルム。 |

| 製品カテゴリ | ヒッププラスチック、GPPSプラスチック |

| 複合タイプ | PS/EVOH/PS、PS/EVOH/PE、PP/PEなど。 |

| 形 | ロール/シート |

| 厚さ | 0.3〜2.0mm |

| 幅 | 300〜850mm |

| パッキング | 内側 +クラフトの外側 +パレット(紙のチューブの直径:76mm、厚さ:10mm) |

| 品質 | 100%処女 |

| 色 | 透明で、自然、黒、白、色、ニーズに応じてカスタマイズされています。 |

| 表面処理 | マット、光沢、群れ。 |

| パフォーマンス | ESD:抗静止、導電性、静的散逸。コロナ;印刷;コーティング;エボ;防水;等 |

| 処理技術 | 熱成形真空を形成する膨らみ、ダイカット。 |

| 硬度 | 剛性/半整形 |

t私たちが提供するヒップシートのYPES

| ヒップシートタイプ | 幅(mm) | 厚さ(mm) | 色 | 抵抗値(ω) |

| ヒップ通常のシート | 300-850 | 0.2-2.0 | 任意/カスタマイズ | / |

| インパクトの高い腰 | 任意/カスタマイズ | / | ||

| ヒップブラック導電性 | 黒 | 104-106 | ||

| ヒップブラック半導電性 | 黒 | 106-109 | ||

| ヒップブラックボリューム導電性 | 黒 | 104-106 | ||

| ヒップポリマーシート | 任意/カスタマイズ | 108 | ||

| ヒップ抗静止シート | 任意/カスタマイズ | 109-1011 | ||

| ヒップでコーティングされたシート | 任意/カスタマイズ | 103-109 |

c腰の導電性プラスチックシートの病気

安定した導電率: 表面抵抗は、10³-10ωの範囲内で制御でき、静的な電力の蓄積と放出を効果的に防ぎ、電子成分の安全性を確保できます。

優れた衝撃強度: 通常のPS材料よりも耐衝撃性が高く、壊れるのは簡単ではなく、パッケージ内の電子製品を保護します。

優れた処理適応性: さまざまな製品要件に適した真空形成、ホットプレス、スタンピング、曲げ、その他の処理方法によって処理できます。

化学腐食抵抗: ほとんどの化学溶媒、酸、アルカリに耐性があり、さまざまな産業環境に適しています。

環境にやさしくリサイクル可能: 再利用し、環境規制に準拠し、企業の生産コストを削減することができます。

a腰の導電性プラスチックシートのDVANTAGES

強力な静電保護能力、敏感な製品を保護します

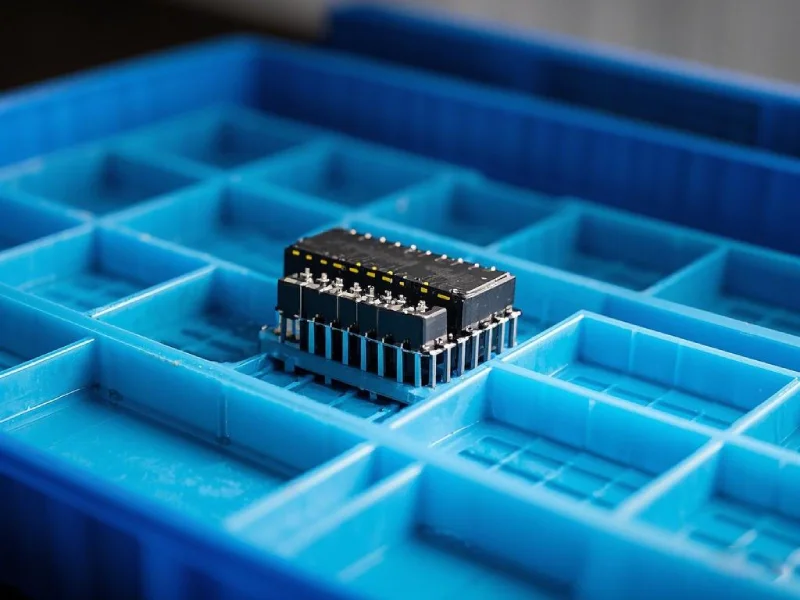

股関節の導電性シートは、静的な電力を効果的に排除し、電子コンポーネント、チップ、PCBボード、およびその他の敏感な製品が静的な電力蓄積によって損傷を受け、製品の資格率を改善することができます。

経済的かつ効率的な、金属およびその他の骨材料を交換します

導電性金属材料と比較して、股関節の導電シートは軽量で低コストで、加工性が良好で、大規模な生産に適しています。

高い機械的強度、耐衝撃性、そして壊れやすいこと

材料は強く、耐久性があり、外部の影響に耐えることができ、輸送と貯蔵中の製品の安全な保護を保証します。

さまざまな処理方法、優れた成形効果に適しています

真空形成、曲げ、スタンピング、その他の方法で処理できます。表面は滑らかで均一で、成形後のサイズは安定しており、さまざまなアプリケーション要件を満たすことができます。

a股関節のプラスチックシートロールのpplication

📌エレクトロニクスおよび半導体産業:抗静止パッケージ:敏感なコンポーネントの静的な損傷を防ぐためのチップトレイ、ICキャリア。

📌医療産業:外科用計器トレイ:粉塵の吸着を回避し、滅菌環境を確保するための抗静止設計。

📌工業製造:精密機械部品の貯蔵、静電敏感な製品の輸送保護

📌自動車産業:電子コンポーネントパッケージングトレイ

c股関節導電性プラスチックシートの乳であるプロセス

導電性充填修正

導電性カーボンブラック、金属繊維、またはカーボンナノチューブをHIPS基板に加えて、材料を導電性全体として加えます。この方法により、材料には内部と表面の両方で導電性特性があり、導電性効果は長期にわたって安定しています。

表面コーティング伝導

股関節シートの表面に導電性コーティングをスプレーして、導電性保護膜を形成します。この方法は、表面抵抗のための特別な要件を持つ製品に適しています。

ブレンドと複合プロセス

腰は導電性ポリマー材料とブレンドされて、材料の処理の利点を維持しながら、材料の骨stat抗特性を与えます。

複合ラミネーションテクノロジー

導電性膜が腰の表面に取り付けられており、材料の機械的強度と耐久性を確保しながら、帯電防止能力を向上させます。

fAQ

r高揚した製品

a試合シェンガン

盛安(上海)新材料有限公司 – プラスチック包装ソリューションのパートナー

2018 年に中国の上海に設立された ShengAn は、プラスチック包装業界に統合ソリューションを提供することに専念する世界有数のパートナーです。高性能素材から完成品や機械に至るまで、当社は世界中のビジネスに力を与えています。

当社の包括的なソリューション

- 先進的なプラスチックシート: 当社は、以下を含むあらゆる範囲の熱可塑性シートを専門としています。 APET、RPET (再生 PET)、PETG、PP、PS、GAG、ESD 対応 多様で要求の厳しい用途に対応する材料。

- 食品グレードの最終製品: 当社は原材料を超えて、次のような高品質のカスタム設計のパッケージを製造しています。 食品グレードのプラスチックトレイ、使い捨てカップ & 蓋、およびカスタム熱成形ブリスター包装。

- 信頼できる機械 & 装置: お客様の生産サイクルを完了するために、当社は効率的な製品を供給し、サポートします。 PET熱成形カップ機およびブリスター包装機。

認定された品質、世界標準

私たちの取り組みは、次のような国際的な認証によって証明されています。 ISO 9001、FSSC、FDA、および GRS、当社の製品が品質、食品の安全性、持続可能性に関する最も厳しい要件を満たしていることを保証します。

ShengAn と提携する理由

- エンドツーエンドの統合: 当社は材料から機械に至るまであらゆるものを提供することでサプライチェーンを合理化し、一貫性、効率性、費用対効果を保証します。

- 品質へのこだわり & 安全性: 当社の生産は、以下を含む厳格な国際認証によって裏付けられています。 ISO 9001、ISO 14001、FSSC、FDA、HACCP、および GRS (RPET 用)、最高の世界基準を満たす製品を保証します。

- 実証済みの優れた製造: 上海の戦略的生産拠点のサポートにより、当社は世界中のクライアントに拡張性と信頼性の高いソリューションとシームレスなサプライ チェーン管理を提供する能力を備えています。