Golden PET Sheet for Thermoforming: Benefits, Applications, and Usage Tips

In the competitive world of packaging and manufacturing, finding materials that combine durability, aesthetic appeal, and processing efficiency is crucial. Golden PET Sheet for Thermoforming represents an innovative solution that’s gaining popularity across various industries. This specialized material offers enhanced properties compared to standard PET sheets, making it ideal for demanding thermoforming applications where visual appeal and performance are equally important.

What Are Golden PET Sheets?

Golden PET sheets are specialized polyethylene terephthalate sheets with a distinctive gold metallic appearance. These sheets are manufactured using high-quality PET resin with specialized additives that create the characteristic golden hue while maintaining excellent thermoforming properties. Unlike standard transparent PET sheets, Golden PET Sheet for Thermoforming combines visual appeal with superior technical performance.

Key Properties of Golden PET Sheets

| Property | Value | Testing Method |

| Specific Gravity (kg/cm³) | 1.27 | ASTM D792 |

| Tensile Strength (kgf/cm²) | 496 | ASTM D638 |

| Impact Strength (J/m) | 98 | ASTM D256 |

| Heat Distortion Temperature (°C) | 77 | ASTM D648 |

| Low Temperature Falling Dart (g) | 791 | ASTM D358 |

| Atmospheric Temperature Falling Dart (g) | 1701 | ASTM D358 |

Golden PET sheets combine the inherent properties of PET with enhanced visual characteristics. They maintain excellent clarity and light transmission while adding a distinctive gold appearance that can elevate product packaging and displays. The material offers good chemical resistance, making it suitable for packaging applications where contact with various substances may occur.

5 Unique Benefits of Golden PET Sheets in Thermoforming

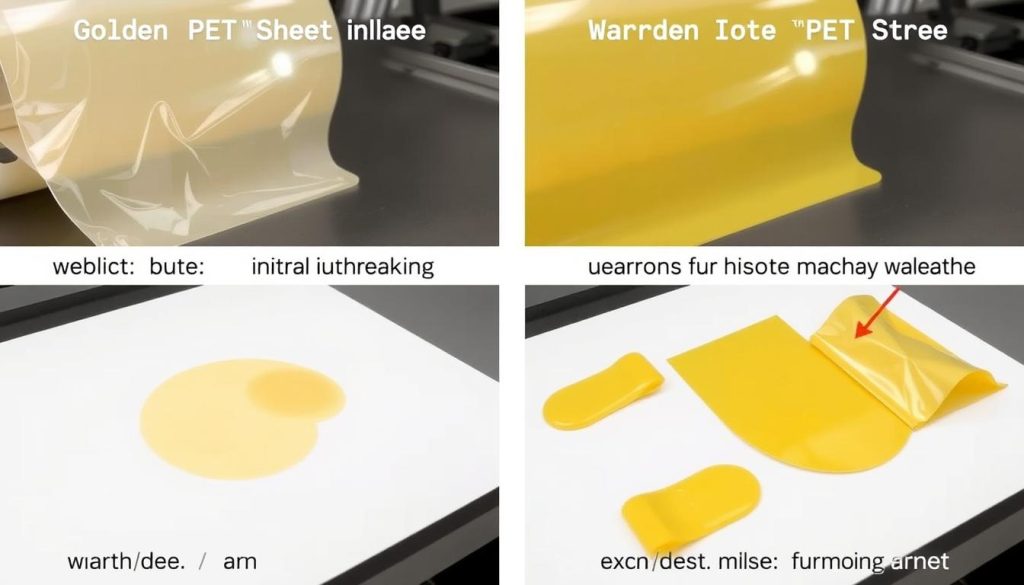

1. Superior Deep Draw Capabilities

Golden PET Sheet for Thermoforming offers exceptional deep draw capabilities, allowing manufacturers to create complex shapes with precise details. This property makes it ideal for packaging designs with intricate geometries that would be challenging with standard materials. The material maintains uniform thickness even in deep-drawn areas, ensuring structural integrity throughout the formed product.

2. Enhanced Visual Appeal

The distinctive golden finish provides a premium appearance that helps products stand out on retail shelves. This metallic aesthetic eliminates the need for additional printing or coating processes, reducing production costs while enhancing visual appeal. The reflective properties of Golden PET sheets create an eye-catching effect that attracts consumer attention.

3. Improved Impact Resistance

With impact strength approaching that of polycarbonate, Golden PET sheets offer superior durability compared to standard PET and acrylic materials. This enhanced impact resistance translates to better product protection during shipping and handling, reducing damage rates and returns. The material’s resilience makes it suitable for applications where durability is a critical requirement.

4. Optimized Processing Efficiency

Golden PET Sheet for Thermoforming features lower forming temperatures than alternative materials, resulting in reduced energy consumption and faster cycle times. The material’s excellent thermal stability prevents warping and ensures consistent results across production runs. These processing efficiencies translate to cost savings and increased throughput for manufacturers.

5. Environmental Sustainability

Golden PET sheets are fully recyclable, aligning with growing consumer demand for sustainable packaging solutions. The material’s durability also extends product lifecycles, reducing waste and environmental impact. For manufacturers committed to sustainability initiatives, Golden PET Sheet for Thermoforming offers an eco-friendly alternative without compromising on performance or aesthetics.

Additional Advantages

- Chemical resistance to common cleaners and substances

- Self-extinguishing properties for improved safety

- Easy die-cutting and punching for secondary processing

- Printability for additional customization options

4 Key Industrial Applications for Golden PET Sheets

1. Premium Food Packaging

Golden PET Sheet for Thermoforming is increasingly used in high-end food packaging applications where visual appeal is paramount. The material’s food-safe properties, combined with its distinctive golden appearance, make it ideal for:

- Luxury confectionery packaging

- Premium bakery product containers

- Gourmet food trays and inserts

- Special edition or seasonal food packaging

The material’s excellent barrier properties help extend product shelf life while its aesthetic qualities enhance brand perception and justify premium pricing.

2. Automotive Components

The automotive industry utilizes Golden PET Sheet for Thermoforming in various interior and exterior applications where both durability and aesthetics are important:

- Decorative interior trim components

- Instrument panel inserts and surrounds

- Door panel components

- Specialized packaging for automotive parts

The material’s impact resistance and ability to withstand temperature variations make it suitable for the demanding conditions found in automotive applications. Its metallic appearance complements modern vehicle interior design trends without the weight penalty of actual metal components.

3. Medical Device Packaging

The healthcare sector benefits from Golden PET Sheet for Thermoforming in specialized medical device packaging applications:

- Sterile barrier packaging for surgical instruments

- Custom trays for medical device kits

- Pharmaceutical blister packaging

- Diagnostic test kit components

The material’s clarity allows for visual inspection of packaged items while providing the necessary barrier properties to maintain sterility. The distinctive gold appearance can also serve as a visual indicator for premium or specialized medical products.

4. Retail Display and Consumer Goods

Golden PET Sheet for Thermoforming creates eye-catching retail displays and consumer product packaging:

- Point-of-purchase displays

- Cosmetic and perfume packaging

- Electronics packaging

- Gift box inserts and windows

The material’s combination of formability, durability, and premium appearance makes it ideal for applications where consumer perception directly impacts purchasing decisions. Brands looking to position products as premium offerings often choose Golden PET sheets to enhance packaging presentation.

Step-by-Step Guide: Optimizing Thermoforming Parameters for Golden PET Sheets

Achieving optimal results with Golden PET Sheet for Thermoforming requires careful attention to processing parameters. Follow this comprehensive guide to maximize quality and efficiency in your thermoforming operations:

1. Material Preparation

- Store Golden PET sheets in a controlled environment (20-25°C, 40-60% humidity)

- Pre-dry sheets at 65-70°C for 4-6 hours if moisture content exceeds 0.15%

- Allow sheets to reach room temperature before processing

- Inspect sheets for any defects or contamination

- Handle with clean gloves to prevent fingerprints on the golden surface

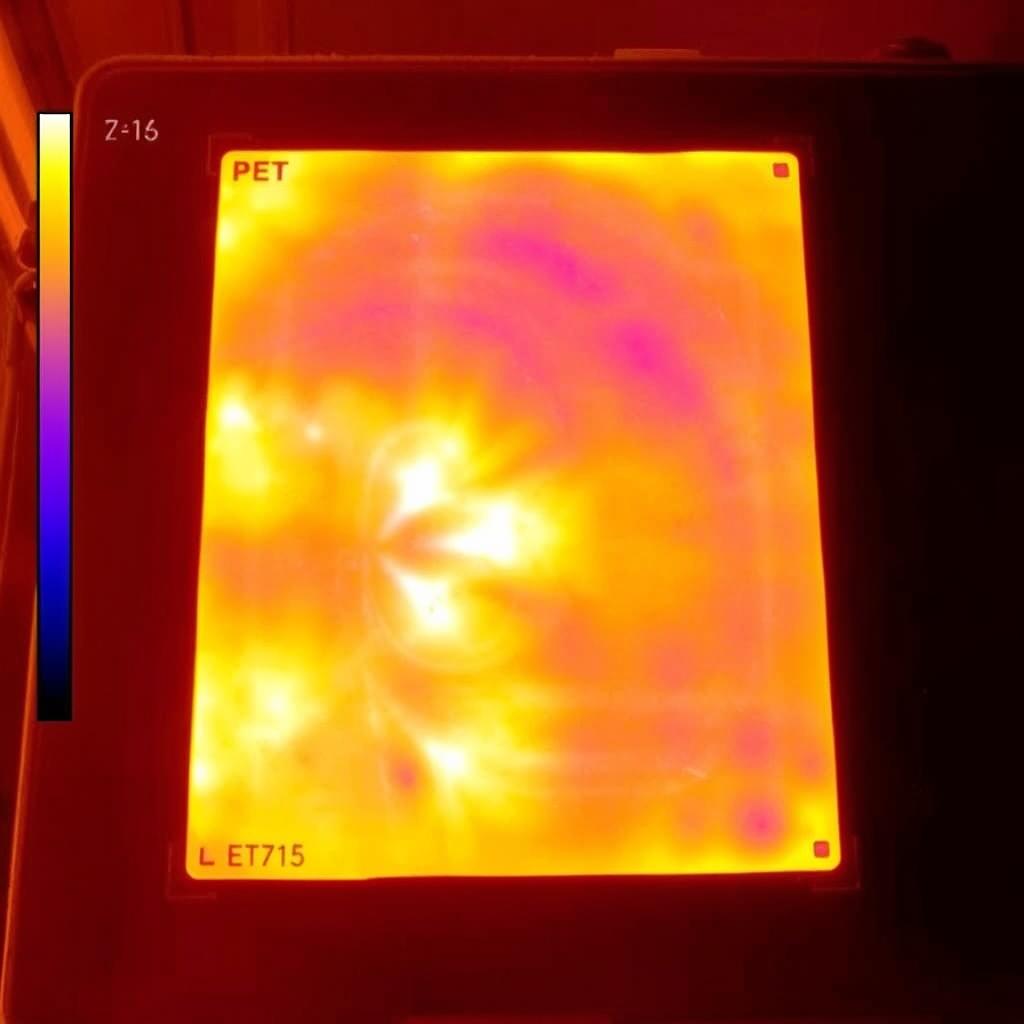

2. Heating Parameters

- Set heating temperature between 120-140°C (248-284°F)

- Implement zoned heating for sheets larger than 600mm × 600mm

- Use infrared temperature measurement to verify surface temperature

- Allow 15-20 seconds per mm of thickness for proper heat penetration

- Maintain consistent heating across the entire sheet surface

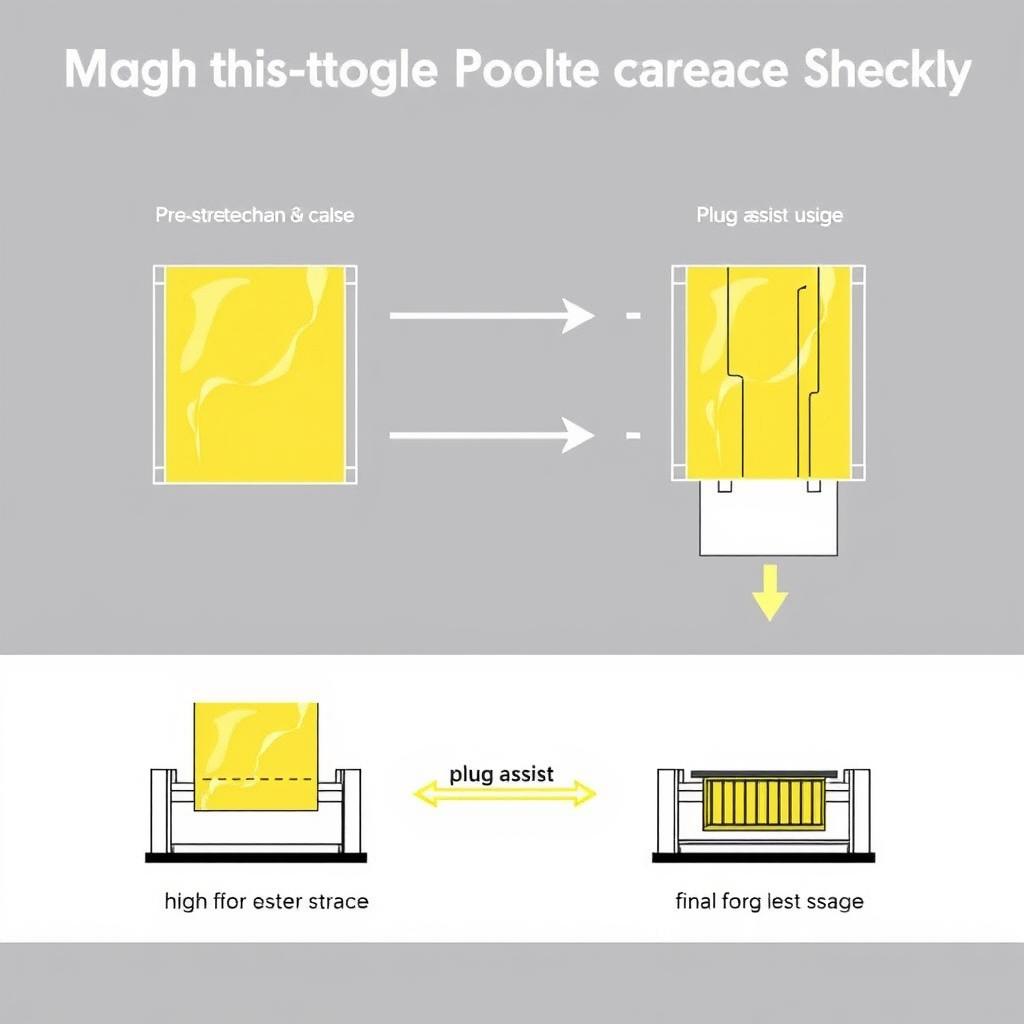

3. Forming Parameters

- Apply forming pressure of 4-6 bar (60-90 psi)

- Utilize plug assists for deep draws to maintain thickness uniformity

- Set vacuum level between 0.7-0.9 bar for optimal detail reproduction

- Apply release agents to molds to prevent sticking

- Consider multi-stage forming for complex geometries

4. Cooling Process

- Maintain mold temperature between 15-25°C (59-77°F)

- Allow cooling time of 1-2 seconds per mm of material thickness

- Implement forced air cooling for faster cycle times

- Ensure uniform cooling to prevent warping

- Verify part temperature is below 40°C before demolding

5. Trimming & Finishing

- Allow parts to fully cool before trimming operations

- Use sharp cutting tools to prevent stress concentration

- Consider automated trimming for consistent results

- Implement dust collection systems to maintain clean environment

- Inspect finished parts for dimensional accuracy

6. Quality Control

- Inspect for uniform golden appearance across the formed part

- Check wall thickness distribution, especially in deep-drawn areas

- Verify dimensional accuracy against specifications

- Test mechanical properties of finished parts

- Document process parameters for successful runs

3 Practical Tips to Avoid Common Thermoforming Defects

Tip 1: Preventing Uneven Thickness

Uneven material distribution is one of the most common challenges when thermoforming Golden PET Sheet for Thermoforming, particularly in deep-draw applications.

Solution Approach

- Implement multi-stage forming with pre-stretching

- Use plug assists designed specifically for your part geometry

- Apply differential heating to provide more heat to areas that will stretch more

- Optimize material distribution by adjusting sheet clamping tension

- Consider increasing initial sheet thickness for challenging geometries

Common Mistakes

- Single-stage forming for complex geometries

- Inadequate plug assist design or material

- Uniform heating for parts with varying draw depths

- Excessive forming speed causing material thinning

- Insufficient material thickness for the application

Tip 2: Eliminating Warping and Dimensional Instability

Golden PET Sheet for Thermoforming can experience warping if processing parameters aren’t properly controlled, leading to parts that don’t meet dimensional specifications.

Solution Approach

- Ensure uniform heating across the entire sheet

- Implement controlled, even cooling of formed parts

- Design molds with appropriate draft angles (minimum 3°)

- Allow sufficient cooling time before demolding

- Store finished parts on flat surfaces during complete cooling

Common Mistakes

- Uneven heating causing internal stresses

- Premature demolding before adequate cooling

- Insufficient draft angles in mold design

- Stacking hot parts causing deformation

- Excessive clamping force creating stress points

Tip 3: Maintaining Optimal Surface Finish

The distinctive golden appearance of Golden PET Sheet for Thermoforming can be compromised by improper handling and processing, resulting in surface defects that diminish visual appeal.

Solution Approach

- Handle sheets with clean gloves to prevent fingerprints

- Maintain clean mold surfaces free of contaminants

- Avoid overheating which can cause surface degradation

- Use appropriate release agents compatible with PET

- Implement clean room practices for premium applications

Common Mistakes

- Bare-hand handling leaving oils on sheet surface

- Dirty or damaged mold surfaces transferring defects

- Excessive heating causing surface blistering

- Incompatible release agents causing clouding

- Dusty processing environment contaminating surfaces

Frequently Asked Questions About Golden PET Sheet for Thermoforming

Can Golden PET sheets be recycled?

Yes, Golden PET Sheet for Thermoforming is fully recyclable. The material can be processed through standard PET recycling streams, though the golden additives may affect the recycled output. For optimal sustainability, consider establishing a closed-loop recycling program for production scrap. Many manufacturers offer take-back programs for post-industrial waste to ensure proper recycling.

What thicknesses are available for Golden PET sheets?

Golden PET Sheet for Thermoforming is typically available in thicknesses ranging from 0.2mm to 2.0mm, with some manufacturers offering up to 4.0mm for specialized applications. Standard sheet sizes include 1220mm × 2440mm and custom widths from 400mm to 1280mm. The optimal thickness depends on your specific application requirements, with thicker sheets providing greater rigidity and thinner sheets offering more economical solutions for less demanding applications.

Is Golden PET sheet food-safe?

Yes, Golden PET Sheet for Thermoforming can be produced to food-safe standards in compliance with FDA regulations and EU directives. When purchasing for food contact applications, ensure the material is specifically certified for food contact and request relevant documentation. Food-grade Golden PET sheets maintain all the aesthetic advantages while meeting strict safety requirements for direct food contact.

How does temperature affect Golden PET sheet properties?

Golden PET Sheet for Thermoforming maintains its structural integrity up to its heat distortion temperature of approximately 77°C (170°F). Above this temperature, the material begins to soften and can deform under load. For applications involving hot-fill products or heated environments, consider the operating temperature range carefully. The material performs well in cold environments and maintains flexibility and impact resistance at temperatures as low as -40°C (-40°F).

What is the minimum order quantity for Golden PET sheets?

Typical minimum order quantities for Golden PET Sheet for Thermoforming range from 500kg to 1000kg, depending on the manufacturer and specific material grade. For smaller quantity needs, some suppliers offer sample programs or maintain stock of standard sizes for smaller orders. Establishing a relationship with a distributor rather than ordering directly from manufacturers can sometimes provide access to smaller quantities.

Conclusion: Maximizing Value with Golden PET Sheet for Thermoforming

Golden PET Sheet for Thermoforming represents an innovative material solution that combines aesthetic appeal with superior technical performance. Its unique properties make it ideal for applications where visual differentiation and premium positioning are as important as functional performance. By understanding the material’s characteristics and optimizing processing parameters, manufacturers can leverage Golden PET sheets to create distinctive products that stand out in competitive markets.

Whether you’re producing high-end food packaging, automotive components, medical device packaging, or retail displays, Golden PET Sheet for Thermoforming offers compelling advantages over standard materials. The enhanced deep draw capabilities, improved impact resistance, and distinctive golden appearance provide both functional and marketing benefits that can justify the premium cost for appropriate applications.

As with any specialized material, success with Golden PET sheets depends on proper material selection, equipment setup, and process control. By following the guidelines outlined in this article and working closely with material suppliers, you can achieve exceptional results that meet both technical requirements and aesthetic goals.