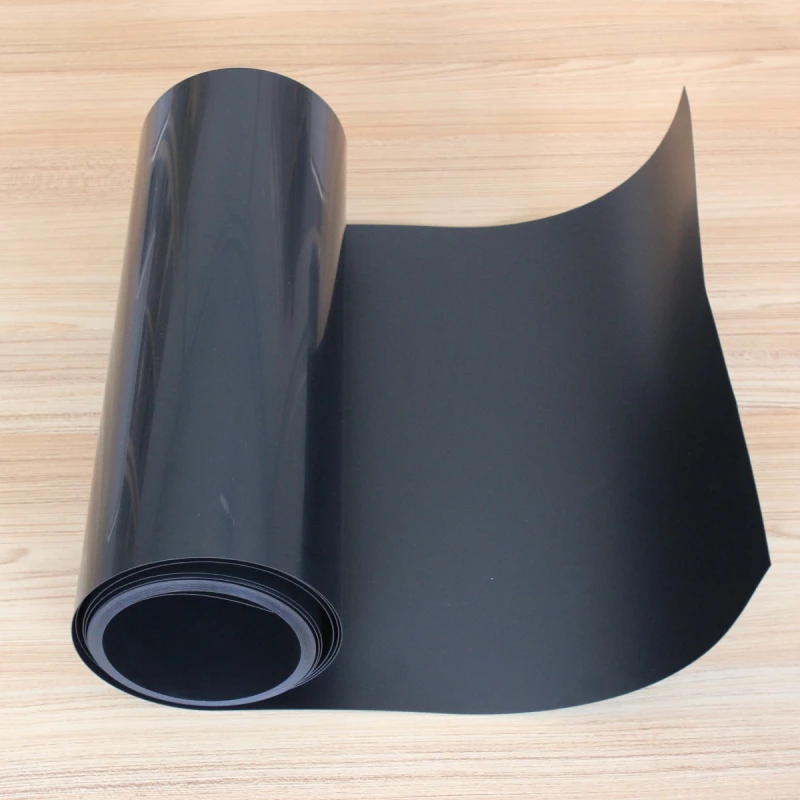

HIPS Plastic Sheet Roll

jentroduction to HIPS Plastic Sheet

High impact polystyrene (HIPS) is a modified polystyrene (PS) plastic. The toughness of the material is enhanced by adding rubber particles, making it more impact-resistant than ordinary PS. HIPS sheets are widely used in packaging, electronics, medical, advertising and other industries due to their excellent processing performance, good thermoforming characteristics, environmental protection and safety.

Specifications of HIPS sheet

| Nom de produit | Feuille PS ; Rouleau PS ; Feuille de polystyrène ; Film PS rigide. |

| Catégorie de produit | Plastique HANCHES, plastique GPPS |

| Type composite | PS/EVOH/PS, PS/EVOH/PE, PP/PE, etc. |

| Forme | Rouleau/Feuille |

| Épaisseur | 0.2~2.0mm |

| Largeur | 300~850mm |

| Emballage | Film PE intérieur + kraft extérieur + palette (diamètre du tube en papier : 76 mm, épaisseur : 10 mm) |

| Qualité | 100% vierge |

| Couleur | Clair, naturel, noir, blanc, couleur, personnalisé selon les besoins. |

| Traitement de surface | Matte, Glossy. |

| Performance | ESD: Anti-static, Conductive, Static dissipative. Corona; Printing; Coating; Waterproof; etc |

| Technologie de traitement | Thermoformage, formage sous vide, cloquage, découpe. |

| Dureté | Rigide/Semi-rigide |

TTypes de feuilles HIPS que nous proposons

| Type de feuille HIPS | Largeur (mm) | Épaisseur (mm) | Couleur | Valeur de résistance (Ω) |

| Feuille normale HANCHES | 300-850 | 0.2-2.0 | Tout/personnalisé | / |

| HANCHES à fort impact | Tout/personnalisé | / | ||

| HIPS conducteur noir | Noir | 104-106 | ||

| HIPS noir semi-conducteur | Noir | 106-109 | ||

| HIPS noir volume conducteur | Noir | 104-106 | ||

| Feuille de polymère HIPS | Tout/personnalisé | 108 | ||

| Feuille antistatique HIPS | Tout/personnalisé | 109-1011 | ||

| Feuille enduite HIPS | Tout/personnalisé | 103-109 |

Characteristics of HIPS plastic sheets

High impact resistance: Compared with ordinary PS, HIPS sheets are more impact-resistant and tougher, reducing the damage rate during processing and transportation.

Excellent processing performance: Easy to thermoform, stamp, print, cut and bond, suitable for a variety of manufacturing needs.

Strong surface adaptability: smooth surface, support silk screen printing, UV printing, spraying, laminating, suitable for billboards, display stands and other high-demand scenes.

Respectueux de l'environnement et recyclable : HIPS materials can be recycled and reused, in line with modern environmental protection requirements.

Chemical resistance: strong tolerance to acid, alkali and salt solutions, suitable for food and medical industries.

UNdvantages of HIPS plastic sheet rolls

🔹 High cost performance: Compared with other engineering plastics, such as ABS, PC, etc., HIPS has a more advantageous price while maintaining good physical properties.

🔹 Good thermoformability: easy to shape after heating, not easy to crack, suitable for large-scale production.

🔹 Diverse choices: different thicknesses (0.3mm-2.0mm), colors (transparent, white, color) and surface treatments (embossed, matte) are available.

🔹 Food safety: in line with international food contact material standards such as FDA and EU 10/2011, safe and non-toxic.

🔹 Lightweight design: moderate density, while ensuring strength, reducing transportation and use costs.

UNapplication de rouleaux de feuilles de plastique HIPS

🔹 Food packaging: yogurt cups, fast food boxes, cake trays (in line with food safety standards).

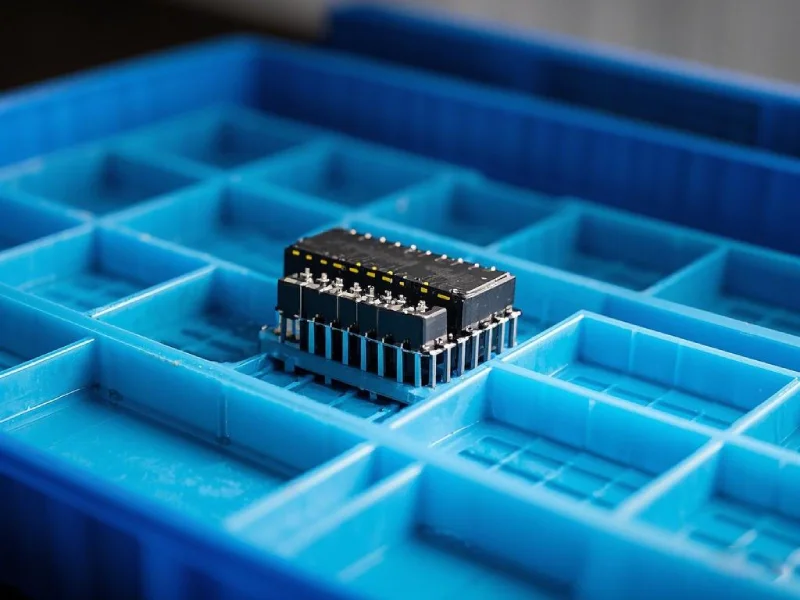

🔹 Industrial packaging: shockproof inner trays and trays for electronic products.

🔹 Medical packaging: disposable medical trays, pharmaceutical packaging boxes.

🔹 Daily necessities packaging: lining of cosmetic packaging boxes, stationery storage boxes, toy packaging folding boxes.

FAQS

RProduits ravis

UNBout Shengan

ShengAn (Shanghai) Nouveaux matériaux Co., Ltd – Votre partenaire en solutions d'emballage plastique

Créé en 2018 à Shanghai, en Chine, ShengAn est un partenaire mondial de premier plan dédié à la fourniture de solutions intégrées pour l'industrie de l'emballage plastique. Des matériaux haute performance aux produits finis et aux machines, nous donnons du pouvoir aux entreprises du monde entier.

Nos solutions complètes

- Feuilles de plastique avancées : Nous sommes spécialisés dans une gamme complète de feuilles thermoplastiques, notamment APET, RPET (PET recyclé), PETG, PP, PS, GAG et ESD matériaux, répondant à des applications diverses et exigeantes.

- Produits finis de qualité alimentaire : Nous allons au-delà des matières premières pour fabriquer des emballages de haute qualité sur mesure, tels que barquettes en plastique alimentaire, gobelets jetables & couvercles et emballage blister thermoformé sur mesure.

- Machines fiables & Équipement: Pour compléter votre cycle de production, nous fournissons et accompagnons efficacement Machines de thermoformage de gobelets PET et machines d'emballage sous blister.

Qualité certifiée, normes mondiales

Notre engagement est validé par des certifications internationales comme ISO 9001, FSSC, FDA et GRS, garantissant que nos produits répondent aux exigences les plus strictes en matière de qualité, de sécurité alimentaire et de durabilité.

Pourquoi s'associer à ShengAn ?

- Intégration de bout en bout : Nous rationalisons votre chaîne d'approvisionnement en offrant tout, des matériaux aux machines, garantissant ainsi la cohérence, l'efficacité et la rentabilité.

- Engagement envers la qualité & Sécurité: Notre production est soutenue par des certifications internationales strictes, notamment ISO 9001, ISO 14001, FSSC, FDA, HACCP et GRS (pour RPET), garantissant des produits répondant aux normes mondiales les plus élevées.

- Excellence de fabrication éprouvée : Soutenus par nos bases de production stratégiques à Shanghai, nous possédons la capacité de fournir des solutions évolutives et fiables et une gestion transparente de la chaîne d'approvisionnement à nos clients du monde entier.