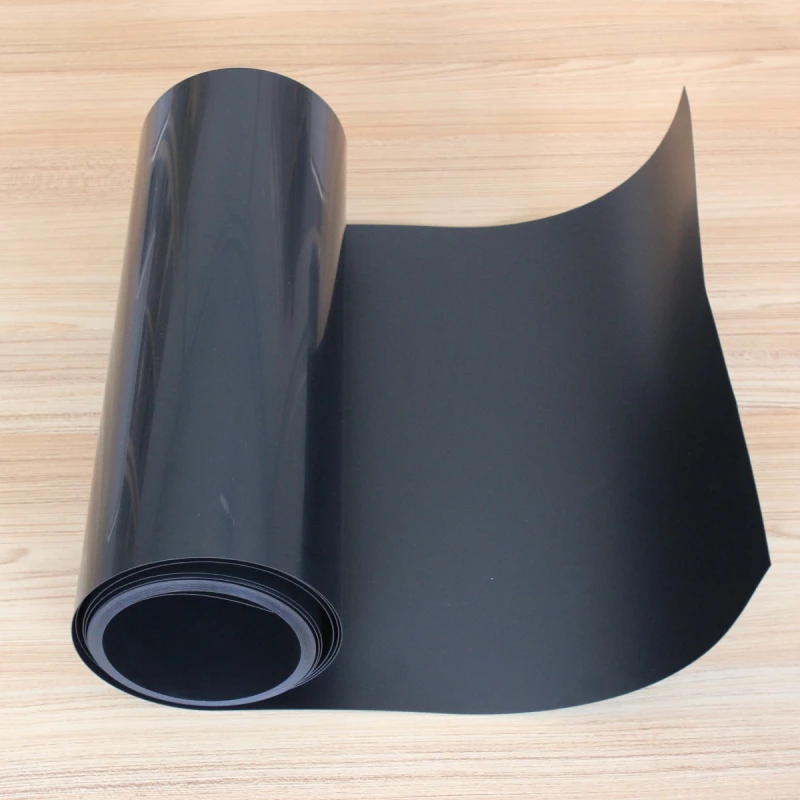

PP Plastic Sheet Roll

IIntroducción a la lámina de plástico PP

La lámina de plástico PP (polipropileno) es un material laminar elaborado a partir de resina de polipropileno mediante un proceso de moldeo por extrusión, con excelente resistencia química, propiedades mecánicas y características de protección ambiental. Las láminas de PP se pueden modificar según diferentes necesidades, como mejorar la dureza, mejorar la transparencia o agregar resistencia a los rayos UV, lo que las hace adecuadas para diversas aplicaciones industriales y de consumo.

SEspecificaciones de la lámina de PP.

| Nombre del producto | Lámina de PP, Lámina de polipropileno, Película rígida de PP. |

| Tipo compuesto | PP/EVW/PP/EVW/PP, PP, PP, etc. |

| Forma | Rollo/Hoja |

| Espesor | 00,2 ~ 2,0 mm |

| Ancho | 300~850 mm |

| PÁGINAS Diámetro del rollo | ≤38 pulgadas |

| Embalaje | Película de PE interior + kraft exterior + palet (diámetro del tubo de papel: 76 mm, espesor: 10 mm) |

| Calidad | 100% virgen |

| Color | Claro, Natural, Negro, Blanco, Color, Personalizado según necesidades. |

| Tratamiento superficial | Mate, Brillante. |

| Actuación | ESD: Antiestático, Conductivo, Disipador de estática. Corona; Impresión; Revestimiento; Impermeable; etc. |

| Tecnología de procesamiento | Termoformado, blister al vacío, troquelado. |

| Dureza | Rígido/Semirrígido |

TTipos de láminas de PP que ofrecemos

| Tipo de hoja de PP | Ancho (mm) | Espesor (mm) | Color | Valor de resistencia (Ω) |

| Hoja normal de PP | 300-850 | 0.2-2.0 | Cualquiera/Personalizado | / |

| Hoja de PP para bandeja congelada. | Cualquiera/Personalizado | / | ||

| Hoja de PP para bandeja de comida cocida. | Cualquiera/Personalizado | / | ||

| PP/PE | Cualquiera/Personalizado | / | ||

| PP/EVOH/PP | Cualquiera/Personalizado | / | ||

| Hoja conductora de PP | Cualquiera/Personalizado | 104-106 |

METROcaracterísticas principales

Excelente resistencia química: Las láminas de PP son resistentes a la erosión causada por productos químicos como ácidos, álcalis y sales, y son adecuadas para embalaje y usos industriales.

Excelentes propiedades mecánicas: Tiene buena tenacidad, resistencia al impacto y resistencia a la tracción, y puede soportar ciertas fuerzas externas sin romperse fácilmente.

Respetuoso con el medio ambiente y reciclable: El PP es un material plástico reciclable que cumple con los requisitos de protección ambiental y reduce la contaminación ambiental.

Buena termoformabilidad: Las láminas de PP son adecuadas para conformado al vacío, doblado, prensado en caliente y otros procesos, y son fáciles de procesar para obtener productos de diversas formas.

Resistencia a altas y bajas temperaturas: Las láminas de PP tienen buena resistencia al calor y algunos materiales de PP modificados pueden soportar altas temperaturas superiores a 100 °C, manteniendo al mismo tiempo cierta tenacidad en ambientes de baja temperatura.

Baja densidad y peso ligero: Las láminas de PP son más livianas que otras láminas de plástico (como PVC y PET), lo que ayuda a reducir el peso del producto y los costos de transporte.

AVentajas de los rollos de láminas de plástico PP.

(1) Seguridad de calidad alimentaria: Las láminas de plástico PP cumplen con los estándares de seguridad en contacto con alimentos, no son tóxicas, son inodoras y son adecuadas para el envasado de alimentos.

(2) Fuerte durabilidad: Resistencia al impacto y al desgarro, apto para embalajes de uso múltiple y fines industriales.

(3) Bajo costo y alta eficiencia: En comparación con otros plásticos de ingeniería, las láminas de PP tienen un precio moderado y un buen rendimiento de procesamiento.

(4) Amplia compatibilidad: Puede coextruirse o laminarse con otros materiales (como PE, EVA, etc.) para mejorar el rendimiento.

AAplicación de rollos de láminas de plástico PP.

🔹 Envases de alimentos: ampliamente utilizados en envases de alimentos congelados, cajas para llevar, recipientes para calentar en microondas, etc.

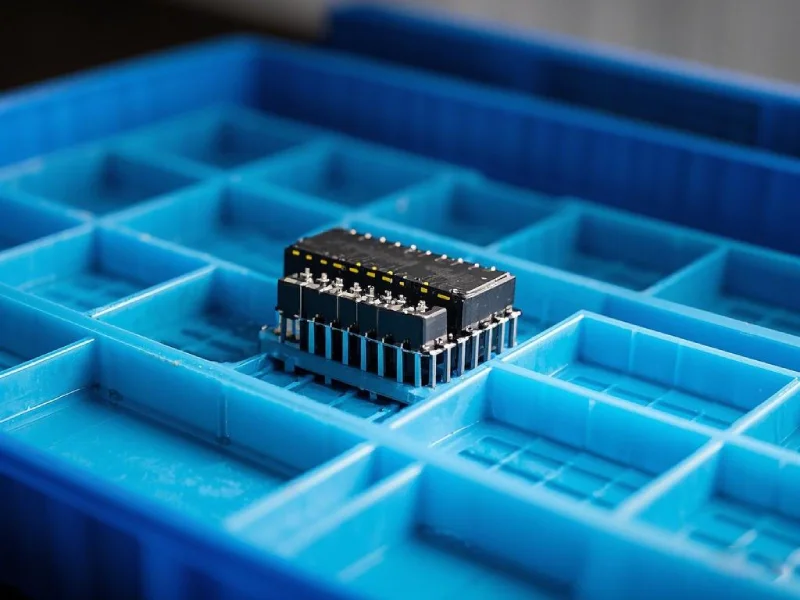

🔹Embalaje de productos electrónicos: utilizado para bandejas antiestáticas, cajas de protección de componentes electrónicos.

🔹 Industria médica: se utiliza para bandejas médicas desechables, gradillas para tubos de ensayo, envases de medicamentos, etc.

🔹 Papelería y artículos de primera necesidad: se utiliza para cajas de archivos, cajas de almacenamiento, vasos de plástico, etc.

FAQS

Riñonalproductos elate

ASHENGAN

ShengAn (Shanghai) Nuevos Materiales Co., Ltd – Su socio en soluciones de embalaje de plástico

Establecida en 2018 en Shanghai, China, ShengAn es un socio global líder dedicado a brindar soluciones integradas para la industria de envases de plástico. Desde materiales de alto rendimiento hasta maquinaria y productos terminados, potenciamos a empresas de todo el mundo.

Nuestras Soluciones Integrales

- Hojas de plástico avanzadas: Nos especializamos en una gama completa de láminas termoplásticas, incluidas APET, RPET (PET reciclado), PETG, PP, PS, GAG y ESD materiales, atendiendo a aplicaciones diversas y exigentes.

- Productos terminados de calidad alimentaria: Vamos más allá de las materias primas para fabricar envases de alta calidad y diseñados a medida, como bandejas de plástico apto para uso alimentario, vasos desechables & tapas y empaques blister termoformados personalizados.

- Maquinaria confiable & Equipo: Para completar su ciclo de producción, suministramos y brindamos soporte eficiente Máquinas termoformadoras de vasos de PET y máquinas envasadoras de blister.

Calidad certificada, estándares globales

Nuestro compromiso está validado por certificaciones internacionales como ISO 9001, FSSC, FDA y GRS, asegurando que nuestros productos cumplan con los más estrictos requisitos de calidad, seguridad alimentaria y sostenibilidad.

¿Por qué asociarse con ShengAn?

- Integración de extremo a extremo: Agilizamos su cadena de suministro ofreciendo todo, desde materiales hasta maquinaria, garantizando coherencia, eficiencia y rentabilidad.

- Compromiso con la Calidad & Seguridad: Nuestra producción está respaldada por estrictas certificaciones internacionales, que incluyen ISO 9001, ISO 14001, FSSC, FDA, HACCP y GRS (para RPET), garantizando productos que cumplen con los más altos estándares globales.

- Excelencia de fabricación comprobada: Con el respaldo de nuestras bases de producción estratégicas en Shanghai, poseemos la capacidad de ofrecer soluciones escalables y confiables y una gestión perfecta de la cadena de suministro para clientes de todo el mundo.