HOPS CONDUCTIVO DE PLÁSCA CONDUCTA

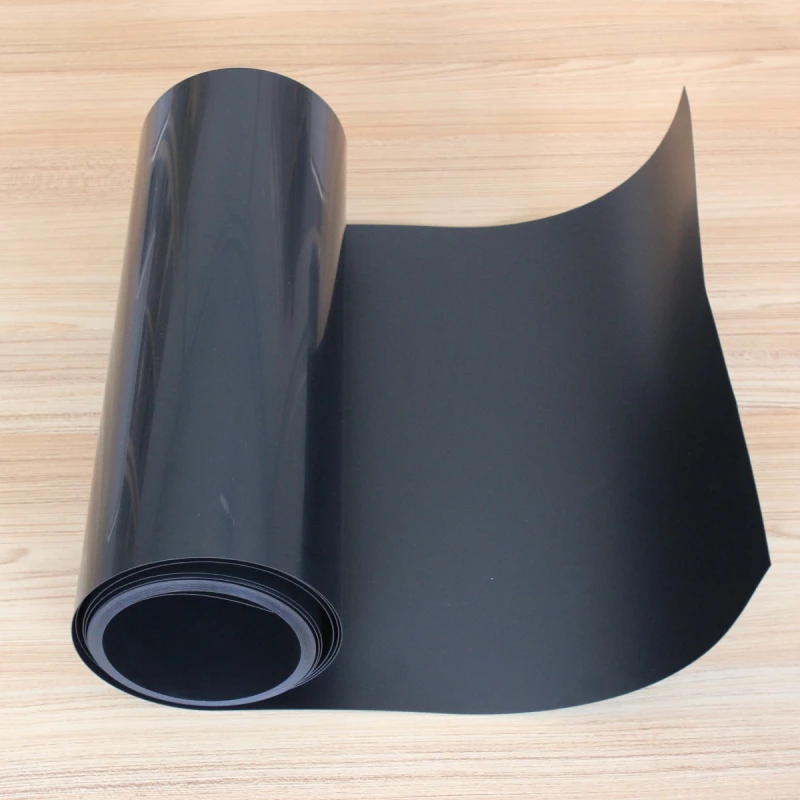

Introduction to HIPS conductive plastic sheet

HIPS conductive plastic sheet is a thermoplastic sheet that adds conductive fillers (such as conductive carbon black, carbon nanotubes, metal fibers, etc.) or uses special coating treatment on the basis of HIPS (high impact polystyrene) to make it have long-lasting and stable conductive properties. It not only maintains the original high impact resistance and excellent molding and processing performance of HIPS, but also gives the material anti-static ability, which is widely used in electronics, medical treatment, industry and other fields.

Specifications of HIPS sheet roll

| Nombre del producto | PS Sheet; PS Roll; Polystyrene Sheet; Rigid PS Film. |

| Categoría de producto | HIPS Plastic, GPPS Plastic |

| Tipo compuesto | PS/EVOH/PS, PS/EVOH/PE, PP/PE, etc. |

| Forma | Rollo/Hoja |

| Espesor | 0.3~2.0mm |

| Ancho | 300~850 mm |

| Embalaje | Película de PE interior + kraft exterior + palet (diámetro del tubo de papel: 76 mm, espesor: 10 mm) |

| Calidad | 100% virgen |

| Color | Claro, Natural, Negro, Blanco, Color, Personalizado según necesidades. |

| Tratamiento superficial | Matte, Glossy, Flocked. |

| Actuación | ESD: Anti-static, Conductive, Static dissipative. Corona; Printing; Coating; EVOH; Waterproof; etc |

| Tecnología de procesamiento | Thermoforming Vacuum Forming Blistering, Die Cutting. |

| Dureza | Rigid/Semi-rigid |

Types of HIPS sheets we offer

| HIPS sheet type | Ancho (mm) | Espesor (mm) | Color | Valor de resistencia (Ω) |

| HIPS normal sheet | 300-850 | 0.2-2.0 | Cualquiera/Personalizado | / |

| High impact HIPS | Cualquiera/Personalizado | / | ||

| HIPS black conductive | Black | 104-106 | ||

| HIPS black semi-conductive | Black | 106-109 | ||

| HIPS black volume conductive | Black | 104-106 | ||

| HIPS polymer sheet | Cualquiera/Personalizado | 108 | ||

| HIPS anti-static sheet | Cualquiera/Personalizado | 109-1011 | ||

| HIPS coated sheet | Cualquiera/Personalizado | 103-109 |

Characteristics of HIPS conductive plastic sheets

Stable conductivity: The surface resistance can be controlled within the range of 10³-10⁶Ω, effectively preventing static electricity accumulation and release, and ensuring the safety of electronic components.

Excellent impact strength: More impact-resistant than ordinary PS materials, not easy to break, protecting electronic products in the package.

Good processing adaptability: It can be processed by vacuum forming, hot pressing, stamping, bending and other processing methods, suitable for different product requirements.

Chemical corrosion resistance: It has good resistance to most chemical solvents, acids and alkalis, and is suitable for a variety of industrial environments.

Respetuoso con el medio ambiente y reciclable: It can be reused, complies with environmental regulations, and reduces the production costs of enterprises.

Advantages of HIPS conductive plastic sheet

Strong electrostatic protection ability, protect sensitive products

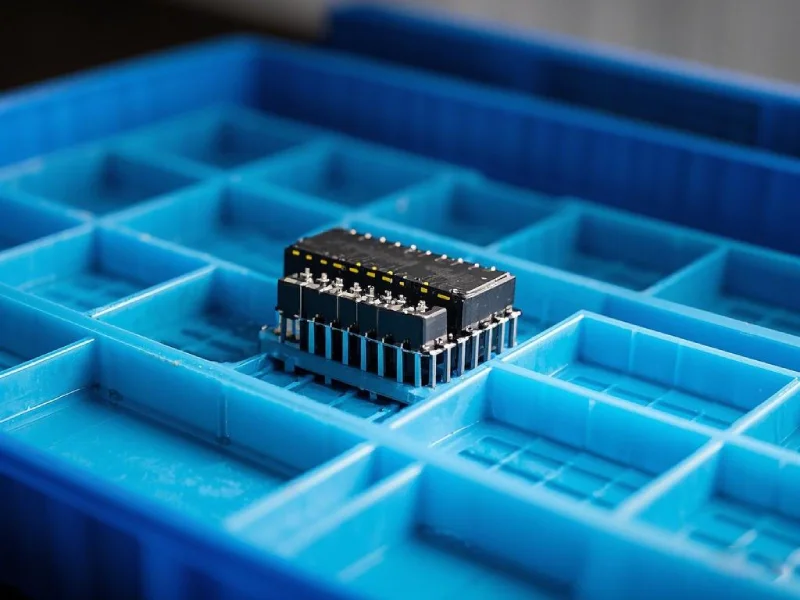

HIPS conductive sheet can effectively eliminate static electricity, prevent electronic components, chips, PCB boards and other sensitive products from being damaged by static electricity accumulation, and improve product qualification rate.

Economical and efficient, replacing metal and other antistatic materials

Compared with conductive metal materials, HIPS conductive sheet is lighter, lower cost, and has good processability, which is more suitable for large-scale production.

High mechanical strength, impact resistance and not easy to break

The material is strong and durable, can withstand external impact, and ensures safe protection for products during transportation and storage.

Suitable for a variety of processing methods, good molding effect

It can be processed by vacuum forming, bending, stamping and other methods. The surface is smooth and uniform, and the size is stable after molding, which can meet different application requirements.

Application of HIPS plastic sheet rolls

📌 Electronics and semiconductor industry: anti-static packaging: chip tray, IC carrier, to prevent static damage to sensitive components.

📌 Medical industry: surgical instrument tray: anti-static design to avoid dust adsorption and ensure a sterile environment.

📌 Industrial manufacturing: storage of precision mechanical parts, transportation protection of electrostatic sensitive products

📌 Automotive industry: electronic component packaging tray

Conductive process of HIPS conductive plastic sheet

Conductive filling modification

Add conductive carbon black, metal fiber or carbon nanotube to the HIPS substrate to make the material conductive as a whole. This method ensures that the material has conductive properties both inside and on the surface, and the conductive effect is long-lasting and stable.

Surface coating conduction

Spray a conductive coating on the surface of the HIPS sheet to form a conductive protective film. This method is suitable for products with special requirements for surface resistance.

Blending and compounding process

HIPS is blended with conductive polymer materials to give the material antistatic properties while maintaining the processing advantages of HIPS.

Composite lamination technology

A conductive film is attached to the surface of the HIPS sheet to improve the antistatic ability while ensuring the mechanical strength and durability of the material.

FAQS

Riñonalproductos e eufóricos

ASHENGAN

ShengAn (Shanghai) Nuevos Materiales Co., Ltd – Su socio en soluciones de embalaje de plástico

Establecida en 2018 en Shanghai, China, ShengAn es un socio global líder dedicado a brindar soluciones integradas para la industria de envases de plástico. Desde materiales de alto rendimiento hasta maquinaria y productos terminados, potenciamos a empresas de todo el mundo.

Nuestras Soluciones Integrales

- Hojas de plástico avanzadas: Nos especializamos en una gama completa de láminas termoplásticas, incluidas APET, RPET (PET reciclado), PETG, PP, PS, GAG y ESD materiales, atendiendo a aplicaciones diversas y exigentes.

- Productos terminados de calidad alimentaria: Vamos más allá de las materias primas para fabricar envases de alta calidad y diseñados a medida, como bandejas de plástico apto para uso alimentario, vasos desechables & tapas y empaques blister termoformados personalizados.

- Maquinaria confiable & Equipo: Para completar su ciclo de producción, suministramos y brindamos soporte eficiente Máquinas termoformadoras de vasos de PET y máquinas envasadoras de blister.

Calidad certificada, estándares globales

Nuestro compromiso está validado por certificaciones internacionales como ISO 9001, FSSC, FDA y GRS, asegurando que nuestros productos cumplan con los más estrictos requisitos de calidad, seguridad alimentaria y sostenibilidad.

¿Por qué asociarse con ShengAn?

- Integración de extremo a extremo: Agilizamos su cadena de suministro ofreciendo todo, desde materiales hasta maquinaria, garantizando coherencia, eficiencia y rentabilidad.

- Compromiso con la Calidad & Seguridad: Nuestra producción está respaldada por estrictas certificaciones internacionales, que incluyen ISO 9001, ISO 14001, FSSC, FDA, HACCP y GRS (para RPET), garantizando productos que cumplen con los más altos estándares globales.

- Excelencia de fabricación comprobada: Con el respaldo de nuestras bases de producción estratégicas en Shanghai, poseemos la capacidad de ofrecer soluciones escalables y confiables y una gestión perfecta de la cadena de suministro para clientes de todo el mundo.