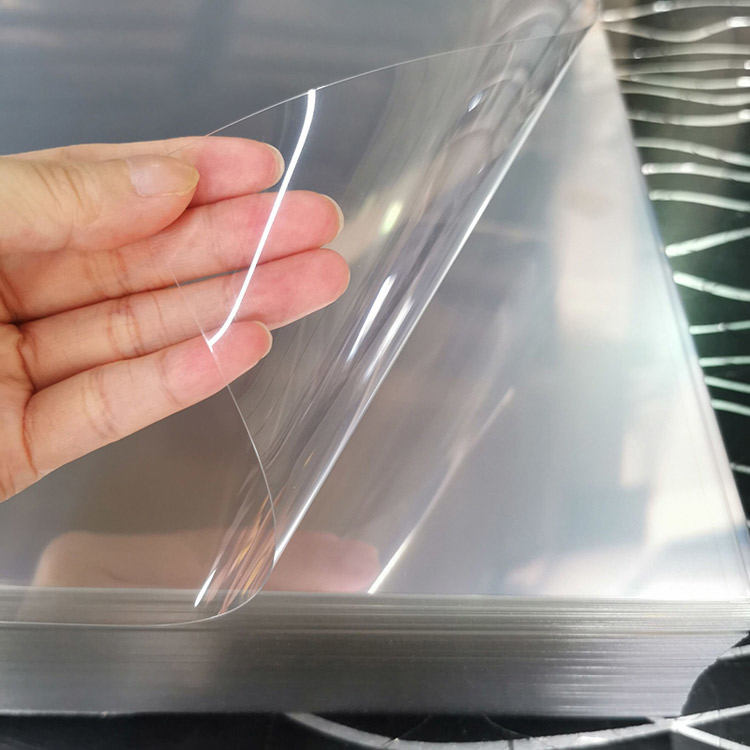

Rollo de láminas de plástico PET de calidad alimentaria

FCaracterísticas del rollo de láminas de plástico PET de calidad alimentaria

La lámina de plástico PET (tereftalato de polietileno) se utiliza ampliamente en el campo del envasado de alimentos debido a sus excelentes propiedades físicas y seguridad alimentaria. Los rollos de láminas de PET de calidad alimentaria están estrictamente controlados por el proceso de producción y cumplen con los estándares internacionales de seguridad en contacto con alimentos para garantizar la higiene y seguridad de los envases de alimentos.

SEspecificaciones de la lámina de PET.

| Categoría de producto | APET, MORDAZA, RPET, PET/PE, etc. |

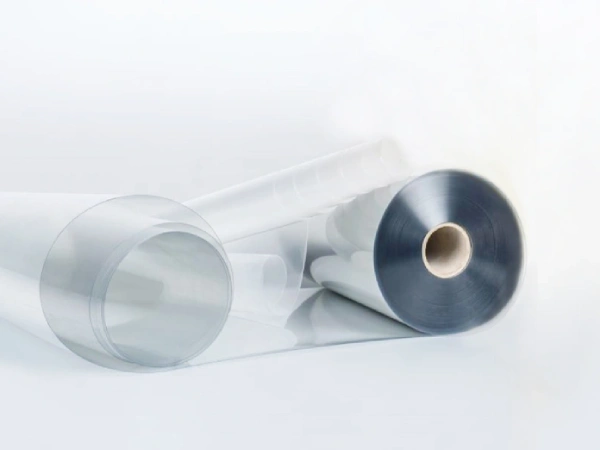

| Forma | Rollo/Hoja |

| Espesor | 00,18 ~ 1,8 mm |

| Ancho | 300~1400 mm |

| Calidad | Virgen/Reciclado |

| Porcentaje de contenido de RPET | 30%-100% |

| MASCOTA Diámetro del rollo | ≤38 pulgadas |

| Color | Claro, blanco, azul, marrón, rosa, verde, amarillo o personalizado |

| Actuación | Antivaho, ESD (antiestático, conductor, disipador de estática), corona, impresión, revestimiento, alto impacto, alta barrera EVOH, impermeable, a prueba de aceite, anti-UV, etc. |

| Embalaje | Película de PE interior + kraft exterior + palet (diámetro del tubo de papel: 76 mm, espesor: 10 mm) |

| Tecnología de procesamiento | Termoformado, formación de blister al vacío, troquelado |

PAGTipo de hoja ET que ofrecemos

| Tipo de lámina de PET | Ancho (mm) | Espesor (mm) | Color | Valor de resistencia (Ω) |

| PET recubierto de silicona | 300-1400 | 0.18-1.8 | Transparente/Otros | / |

| hoja RPET | Transparente/Otros | / | ||

| hoja mordaza | Transparente/Otros | / | ||

| PET antivaho | Transparente/Otros | / | ||

| PET de alto impacto | Transparente/Otros | / | ||

| laminación de PET PE | Transparente/Otros | / | ||

| Hoja de PET para electrónica. | ||||

| PET conductivo | 300-1400 | 0.18-1.8 | Transparente/Otros | 104-106 |

| PET semiconductor | Transparente/Otros | 106-109 | ||

| PET antiestático | Transparente/Otros | 109-1011 | ||

| PET recubierto | Transparente/Otros | 103-106 | ||

METROcaracterísticas principales

Seguridad de calidad alimentaria: Cumple con las normas de la FDA, la UE y otras normas sobre contacto con alimentos, no es tóxico ni tiene sabor, es seguro y respetuoso con el medio ambiente.

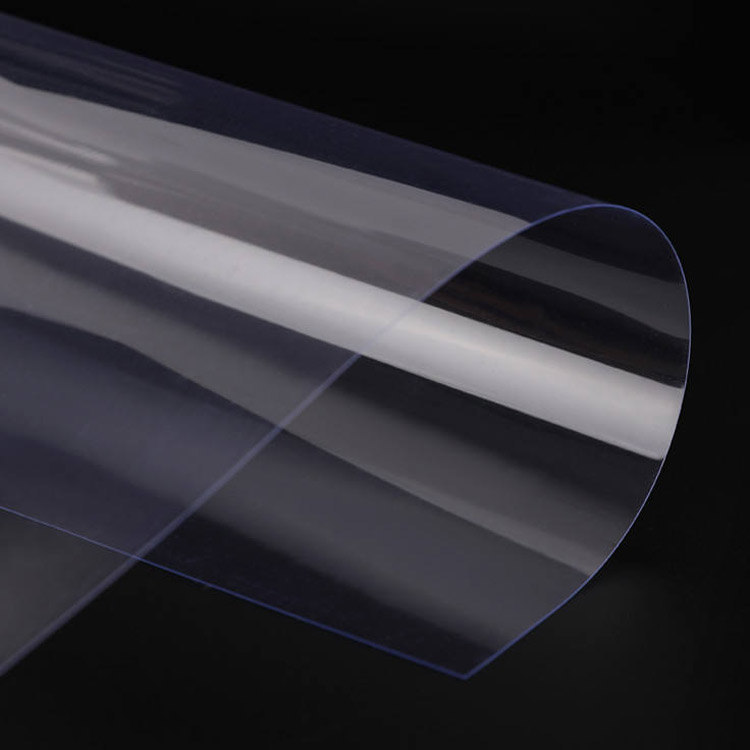

Alta transparencia: Con excelentes propiedades ópticas y alta transmitancia de luz, la apariencia de los alimentos envasados es claramente visible.

Alta resistencia y resistencia al impacto: En comparación con otros materiales plásticos, el PET tiene mayor tenacidad y resistencia al impacto para garantizar la estabilidad del embalaje.

Buena resistencia a la temperatura: Se puede utilizar en un rango de -40 ℃ a +70 ℃, adecuado para envasado de alimentos refrigerados y a temperatura ambiente.

Buena resistencia química: Resistente al aceite, ácidos y álcalis, no reacciona químicamente fácilmente con los alimentos, lo que garantiza el sabor original de los alimentos.

Respetuoso con el medio ambiente y reciclable: El PET es un plástico reciclable que se ajusta a la tendencia de protección ambiental ecológica y reduce la contaminación ambiental.

AVentajas de los rollos de láminas de plástico PET de calidad alimentaria.

(1) Excelente desempeño en seguridad alimentaria

El material PET en sí no contiene sustancias nocivas como BPA y plastificantes, lo que garantiza la salud y seguridad de los alimentos.

Luego de un estricto control del proceso de producción, cumple con los estándares internacionales de seguridad alimentaria, como FDA (U.S. Food and Drug Administration), UE 10/2011 (Reglamento de la UE sobre materiales en contacto con alimentos), etc.

(2) Alta transparencia y buen efecto de visualización.

La transmitancia de luz de las láminas de PET puede alcanzar más del 90%, lo que hace que los alimentos envasados sean más atractivos y convenientes para que los consumidores comprueben la calidad del producto.

Puede utilizarse en envases de alimentos de alta gama para aumentar el valor añadido del producto y la competitividad en el mercado.

(3) Excelentes propiedades mecánicas

Tiene buena resistencia al impacto y a la tracción, no es fácil de romper durante el transporte y almacenamiento y garantiza la seguridad alimentaria.

El diseño liviano reduce efectivamente el costo de los materiales de embalaje, al tiempo que facilita el transporte y el almacenamiento.

(4) Fuerte resistencia a la temperatura, adecuada para una variedad de necesidades de envasado de alimentos

La lámina de PET puede soportar ambientes refrigerados (-40 ℃) y es adecuada para envasar alimentos congelados, como bebidas frías, productos lácteos, carne congelada, etc.

Se mantiene estable en ambiente de alta temperatura (dentro de 70 ℃) y se puede utilizar para envasar alimentos a temperatura ambiente, como pasteles, nueces, dulces, etc.

(5) Fácil de procesar y puede someterse a una variedad de tratamientos secundarios.

Es adecuado para tecnologías de procesamiento como termoformado, blisterado, estampado, doblado, etc., y puede usarse para fabricar cajas de envasado de alimentos y bandejas blister de diferentes formas.

La superficie se puede imprimir, recubrir, metalizar, etc. para satisfacer las necesidades de embalaje personalizadas.

(6) Respetuoso con el medio ambiente y reciclable, en línea con la tendencia del desarrollo sostenible.

El plástico PET es un material 100% reciclable y respetuoso con el medio ambiente. Después de su uso, se puede convertir en materiales de embalaje de alimentos para reducir la contaminación plástica.

Cumple con las políticas globales de protección ambiental verde y es favorecido por el mercado y los consumidores.

AAplicación de rollos de láminas de plástico PET de calidad alimentaria.

Debido a sus propiedades superiores, los rollos de láminas de PET de calidad alimentaria se utilizan ampliamente en diversos campos del envasado de alimentos, incluidas, entre otras, las siguientes categorías:

PAGProceso de producción de rollos de láminas de plástico PET de calidad alimentaria.

(1) Preparación de materia prima

Seleccione partículas de resina PET de calidad alimentaria para garantizar que el material sea puro y libre de impurezas.

Agregue antioxidantes, inhibidores de rayos UV, etc. para mejorar la estabilidad de las láminas de PET.

(2) Moldeo por extrusión

Las partículas de resina de PET se funden en una extrusora de alta temperatura y se extruyen a través de una matriz en T para formar una lámina uniforme.

El espesor de la lámina se controla dentro del rango de 0,2 mm a 2 mm y se puede personalizar según las necesidades del cliente.

(3) Enfriamiento y conformación

El enfriamiento rápido a través de rodillos de enfriamiento garantiza que la superficie de la hoja sea lisa y transparente.

Controle con precisión el espesor para mejorar la uniformidad y las propiedades físicas de la lámina.

(4) Bobinado y embalaje

Adopte equipos de bobinado automático de alta precisión para garantizar que los rollos de láminas de PET estén apretados y limpios, sin arrugas ni burbujas.

Realice una inspección de calidad para garantizar que cada rollo de lámina de PET cumpla con los estándares de seguridad alimentaria.

(5) Procesamiento posterior (opcional)

La lámina se puede imprimir, recubrir, laminar, metalizar, etc. para mejorar el efecto decorativo y la funcionalidad del embalaje.

Las funciones especiales como antivaho, antiestático y antibacteriano se pueden personalizar según las necesidades del cliente para cumplir con los diferentes requisitos de envasado de alimentos.

Los rollos de láminas de plástico PET de calidad alimentaria se han convertido en una opción ideal para el envasado de alimentos moderno debido a su excelente seguridad alimentaria, alta transparencia, buen rendimiento de procesamiento, resistencia a la temperatura y características reciclables respetuosas con el medio ambiente. Se utilizan ampliamente en bandejas de alimentos, cajas de embalaje transparentes, botellas de bebidas, cajas de pasteles, etc., satisfaciendo la demanda del mercado de materiales de embalaje seguros, hermosos y respetuosos con el medio ambiente.

Si necesita rollos de láminas de plástico PET apto para uso alimentario de alta calidad, contáctenos para obtener más información y muestras gratuitas.

Riñonalproductos elate

ASHENGAN

ShengAn (Shanghai) Nuevos Materiales Co., Ltd – Su socio en soluciones de embalaje de plástico

Establecida en 2018 en Shanghai, China, ShengAn es un socio global líder dedicado a brindar soluciones integradas para la industria de envases de plástico. Desde materiales de alto rendimiento hasta maquinaria y productos terminados, potenciamos a empresas de todo el mundo.

Nuestras Soluciones Integrales

- Hojas de plástico avanzadas: Nos especializamos en una gama completa de láminas termoplásticas, incluidas APET, RPET (PET reciclado), PETG, PP, PS, GAG y ESD materiales, atendiendo a aplicaciones diversas y exigentes.

- Productos terminados de calidad alimentaria: Vamos más allá de las materias primas para fabricar envases de alta calidad y diseñados a medida, como bandejas de plástico apto para uso alimentario, vasos desechables & tapas y empaques blister termoformados personalizados.

- Maquinaria confiable & Equipo: Para completar su ciclo de producción, suministramos y brindamos soporte eficiente Máquinas termoformadoras de vasos de PET y máquinas envasadoras de blister.

Calidad certificada, estándares globales

Nuestro compromiso está validado por certificaciones internacionales como ISO 9001, FSSC, FDA y GRS, asegurando que nuestros productos cumplan con los más estrictos requisitos de calidad, seguridad alimentaria y sostenibilidad.

¿Por qué asociarse con ShengAn?

- Integración de extremo a extremo: Agilizamos su cadena de suministro ofreciendo todo, desde materiales hasta maquinaria, garantizando coherencia, eficiencia y rentabilidad.

- Compromiso con la Calidad & Seguridad: Nuestra producción está respaldada por estrictas certificaciones internacionales, que incluyen ISO 9001, ISO 14001, FSSC, FDA, HACCP y GRS (para RPET), garantizando productos que cumplen con los más altos estándares globales.

- Excelencia de fabricación comprobada: Con el respaldo de nuestras bases de producción estratégicas en Shanghai, poseemos la capacidad de ofrecer soluciones escalables y confiables y una gestión perfecta de la cadena de suministro para clientes de todo el mundo.