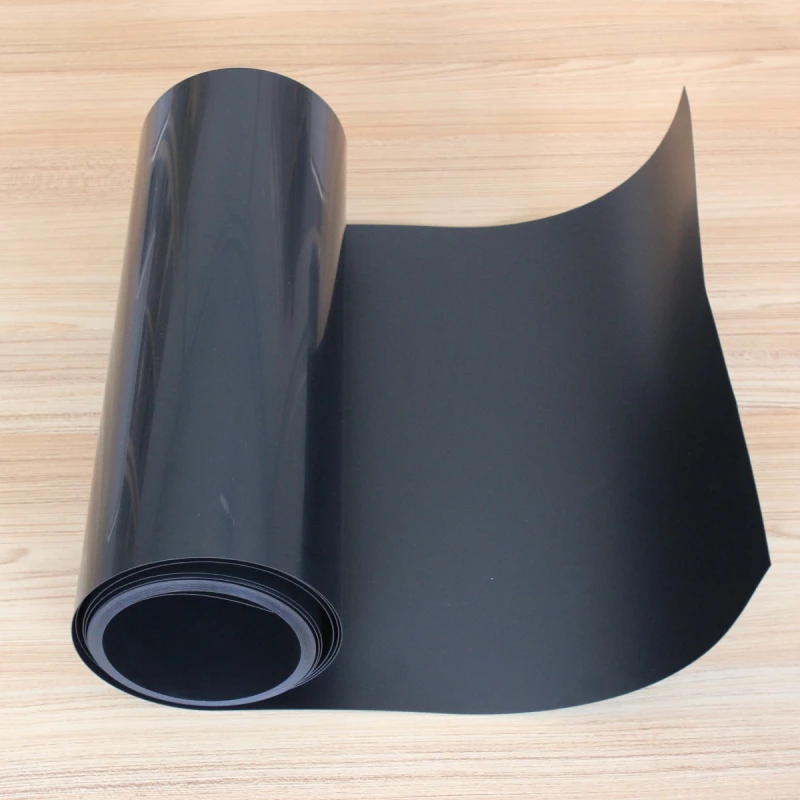

ورقة بلاستيكية موصلة الوركين

Introduction to HIPS conductive plastic sheet

HIPS conductive plastic sheet is a thermoplastic sheet that adds conductive fillers (such as conductive carbon black, carbon nanotubes, metal fibers, etc.) or uses special coating treatment on the basis of HIPS (high impact polystyrene) to make it have long-lasting and stable conductive properties. It not only maintains the original high impact resistance and excellent molding and processing performance of HIPS, but also gives the material anti-static ability, which is widely used in electronics, medical treatment, industry and other fields.

قpecifications of HIPS sheet roll

| اسم المنتج | PS Sheet; PS Roll; Polystyrene Sheet; Rigid PS Film. |

| Product Category | HIPS Plastic, GPPS Plastic |

| Composite Type | PS/EVOH/PS, PS/EVOH/PE, PP/PE, etc. |

| شكل | Roll/Sheet |

| سماكة | 0.3~2.0mm |

| عرض | 300~850mm |

| التعبئة | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Quality | 100% virgin |

| لون | Clear, Natural, Black, White, Color, Customized according to needs. |

| Surface Treatment | Matte, Glossy, Flocked. |

| Performance | ESD: Anti-static, Conductive, Static dissipative. Corona; Printing; Coating; EVOH; Waterproof; etc |

| Processing technology | Thermoforming Vacuum Forming Blistering, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

رypes of HIPS sheets we offer

| HIPS sheet type | Width (mm) | Thickness (mm) | لون | Resistance value (Ω) |

| HIPS normal sheet | 300-850 | 0.2-2.0 | Any/Customized | / |

| High impact HIPS | Any/Customized | / | ||

| HIPS black conductive | Black | 104-106 | ||

| HIPS black semi-conductive | Black | 106-109 | ||

| HIPS black volume conductive | Black | 104-106 | ||

| HIPS polymer sheet | Any/Customized | 108 | ||

| HIPS anti-static sheet | Any/Customized | 109-1011 | ||

| HIPS coated sheet | Any/Customized | 103-109 |

جharacteristics of HIPS conductive plastic sheets

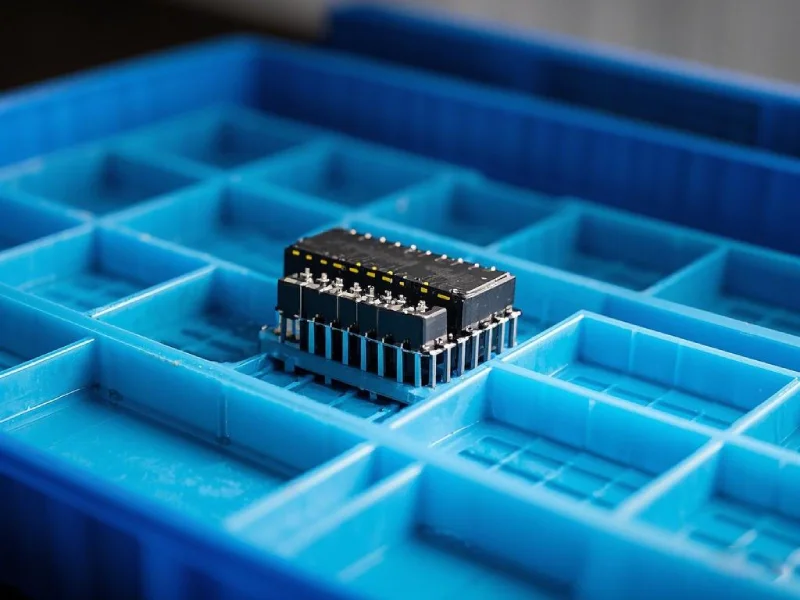

Stable conductivity: The surface resistance can be controlled within the range of 10³-10⁶Ω, effectively preventing static electricity accumulation and release, and ensuring the safety of electronic components.

Excellent impact strength: More impact-resistant than ordinary PS materials, not easy to break, protecting electronic products in the package.

Good processing adaptability: It can be processed by vacuum forming, hot pressing, stamping, bending and other processing methods, suitable for different product requirements.

Chemical corrosion resistance: It has good resistance to most chemical solvents, acids and alkalis, and is suitable for a variety of industrial environments.

صديقة للبيئة وقابلة لإعادة التدوير: It can be reused, complies with environmental regulations, and reduces the production costs of enterprises.

أdvantages of HIPS conductive plastic sheet

Strong electrostatic protection ability, protect sensitive products

HIPS conductive sheet can effectively eliminate static electricity, prevent electronic components, chips, PCB boards and other sensitive products from being damaged by static electricity accumulation, and improve product qualification rate.

Economical and efficient, replacing metal and other antistatic materials

Compared with conductive metal materials, HIPS conductive sheet is lighter, lower cost, and has good processability, which is more suitable for large-scale production.

High mechanical strength, impact resistance and not easy to break

The material is strong and durable, can withstand external impact, and ensures safe protection for products during transportation and storage.

Suitable for a variety of processing methods, good molding effect

It can be processed by vacuum forming, bending, stamping and other methods. The surface is smooth and uniform, and the size is stable after molding, which can meet different application requirements.

أpplication of HIPS plastic sheet rolls

📌 Electronics and semiconductor industry: anti-static packaging: chip tray, IC carrier, to prevent static damage to sensitive components.

📌 Medical industry: surgical instrument tray: anti-static design to avoid dust adsorption and ensure a sterile environment.

📌 Industrial manufacturing: storage of precision mechanical parts, transportation protection of electrostatic sensitive products

📌 Automotive industry: electronic component packaging tray

جonductive process of HIPS conductive plastic sheet

Conductive filling modification

Add conductive carbon black, metal fiber or carbon nanotube to the HIPS substrate to make the material conductive as a whole. This method ensures that the material has conductive properties both inside and on the surface, and the conductive effect is long-lasting and stable.

Surface coating conduction

Spray a conductive coating on the surface of the HIPS sheet to form a conductive protective film. This method is suitable for products with special requirements for surface resistance.

Blending and compounding process

HIPS is blended with conductive polymer materials to give the material antistatic properties while maintaining the processing advantages of HIPS.

Composite lamination technology

A conductive film is attached to the surface of the HIPS sheet to improve the antistatic ability while ensuring the mechanical strength and durability of the material.

وAQS

صالمنتجات المكررة

أنوبة شينجان

شركة شنغان (شنغهاي) للمواد الجديدة المحدودة – شريكك في حلول التغليف البلاستيكية

تأسست ShengAn في عام 2018 في شنغهاي، الصين، وهي شريك عالمي رائد مكرس لتقديم حلول متكاملة لصناعة التعبئة والتغليف البلاستيكية. بدءًا من المواد عالية الأداء وحتى المنتجات النهائية والآلات، نقوم بتمكين الشركات في جميع أنحاء العالم.

حلولنا الشاملة

- صفائح بلاستيكية متقدمة: نحن متخصصون في مجموعة كاملة من الصفائح البلاستيكية الحرارية، بما في ذلك APET، وRPET (PET المعاد تدويره)، وPETG، وPP، وPS، وGAG، وآمن ESD المواد، وتلبية التطبيقات المتنوعة والمتطلبة.

- المنتجات النهائية المخصصة للطعام: نحن نتجاوز المواد الخام لتصنيع عبوات عالية الجودة ومصممة خصيصًا، مثل صواني بلاستيكية صالحة للطعام، وأكواب يمكن التخلص منها & الأغطية، وتغليف نفطة مخصصة بالحرارة.

- آلات موثوقة & معدات: لإكمال دورة الإنتاج الخاصة بك، نحن نوفر وندعم بكفاءة ماكينات تشكيل الأكواب الحرارية PET وماكينات تعبئة الفقاعة.

جودة معتمدة، معايير عالمية

يتم التحقق من صحة التزامنا من خلال الشهادات الدولية مثل ISO 9001، FSSC، FDA، وGRS، مما يضمن أن منتجاتنا تلبي المتطلبات الأكثر صرامة للجودة وسلامة الأغذية والاستدامة.

لماذا الشراكة مع ShengAn؟

- التكامل الشامل: نحن نقوم بتبسيط سلسلة التوريد الخاصة بك من خلال تقديم كل شيء بدءًا من المواد وحتى الآلات، مما يضمن الاتساق والكفاءة والفعالية من حيث التكلفة.

- الالتزام بالجودة & أمان: إنتاجنا مدعوم بشهادات دولية صارمة، بما في ذلك ISO 9001، ISO 14001، FSSC، FDA، HACCP، وGRS (لـ RPET)، ضمان المنتجات التي تلبي أعلى المعايير العالمية.

- التميز التصنيعي المُثبت: وبدعم من قواعد الإنتاج الإستراتيجية الخاصة بنا في شنغهاي، فإننا نمتلك القدرة على تقديم حلول موثوقة وقابلة للتطوير وإدارة سلسة لسلسلة التوريد للعملاء في جميع أنحاء العالم.