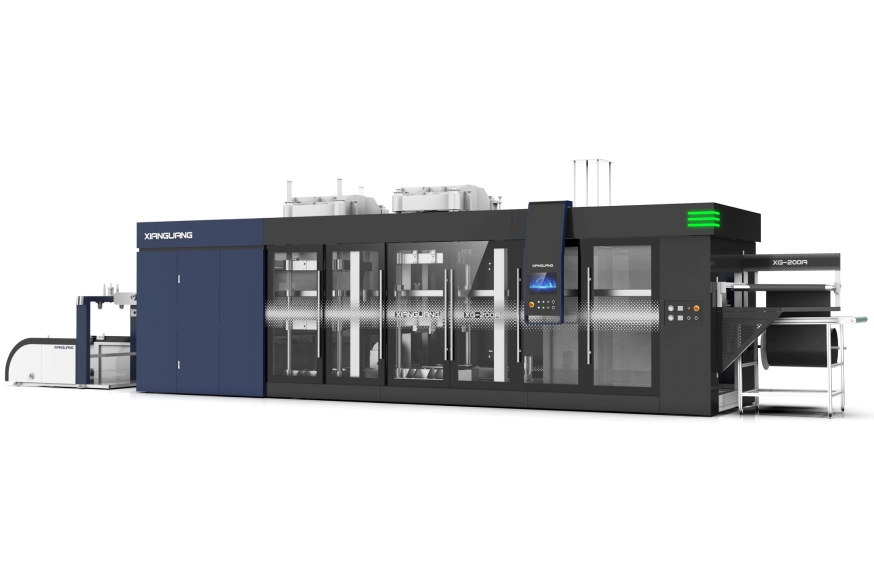

آلة تشكيل الضغط الإيجابية والسلبية التلقائية التلقائية التلقائية الكاملة

XG-A-3-3 High-Efficiency Programmable Plastic Pneumatic Thermoforming Machine, suitable for the forming of various plastic sheets such as HIPS, PLA, BOPS, PS, PP, PVC, PET, ABS, etc.

هquipment Overview

Feature:

ال XG-A-3-3 High-Efficiency Programmable Plastic Pneumatic Thermoforming Machine applies advanced plastic sheet forming technology and integrates machine, electricity, and air systems into one design. It utilizes a microcomputer and industrial control programmable PLC for operation, with an HMI (Human-Machine Interface) system.

The equipment includes a square tunnel-type imported radiation heater, capable of forming both male and female molds, and a laser blade cutting system. The process flow includes heating, forming, punching, cutting, stacking, and counting, which are all part of a multi-station production line.

The production line operates synchronously, employing the latest forming technology to reduce labor, prevent secondary contamination, save materials, improve product quality and compliance, significantly increase production efficiency, and enhance ease of operation, reliability, and functionality. It is an automated production line for sheet thermoforming and automatic punching and cutting of products.

Application:

Suitable for the forming of various plastic sheets such as HIPS, PLA, BOPS, PS, PP, PVC, PET, ABS, etc. The machine can produce high transparency, high stretch, shallow stretch, round, square, irregular, bi-directional stretching, flange, and other products. These include boxes, trays, bowls, lids, industrial packaging, electronic trays, food packaging, stationery packaging, cosmetic packaging, and other plastic packaging products.

رالمعلمات التقنية

| Term Description | Technical Parameters |

|---|---|

| Forming Mold Area | 850mm × 750mm |

| Forming Mold Area | 350mm × 360mm |

| Sheet Width | 800mm |

| Sheet Width | 390mm |

| ارتفاع التشكيل | Male mold: 130mm, Female mold: 120mm |

| Material Thickness | 0.15—2.0mm |

| Forming Speed | 4-45 cycles/min (depending on product) |

| Sheet Roll Diameter | 1000mm (500kg) |

| Forming Mold Stroke | Upper: 150mm, Lower: 150mm |

| Cutting Mold Stroke | Upper: 250mm, Lower: 150mm |

| Punching Mold Stroke | 50mm |

| Cutting Mold Stroke | 50mm |

| Cutting Force | 80 tons (for knife length ≤ 10 meters) |

| Stacking System | 2.0kw and 1.5kw Delta servo motors from Taiwan, with stacking options for high products (<130mm) with hanging points to stack down, and low products (<80mm) with robotic arm either inside or outside the mold, 3 working modes available. |

| Forming Station | Lower servo motor cam lever linkage with hard tooth gear reducer drive, upper servo motor cam lever linkage with hard tooth gear reducer drive. |

| Cutting Station | Lower servo motor cam lever linkage with hard tooth gear reducer drive, upper servo motor cam lever linkage with hard tooth gear reducer direct punching. |

| Cooling Method | High-pressure, large flow circulation water cooling for molds |

| Client Air Source (external) | Air supply ≥ 5.5m³/min, air pressure 0.6~0.8 MPa |

| مزود الطاقة | 380V/50HZ (Three-phase five-wire) |

| Total Power | Installed power: 138KW (Normal operating power approx. 30-60KW) |

| Total Weight (Reference) | 15.5T |

| أبعاد | 14500 × 2000 × 3000mm (for reference) |

| Mold Temperature Monitoring | Temperature gauge to display actual mold temperature, ensuring product quality and production efficiency in real-time. |

| Value Positioning | A. Integrated forming, cutting, and stacking system for smoother processing and lower energy consumption. B. Forming and cutting stations use sturdy mechanical structures with cam levers and roller bearings to ensure perfect forming and cutting. |

| Forming Method | Positive and negative pressure hot press thermoforming |

| Cutting Station | Expandable mold table design, easy, safe, and quick mold replacement with laser cutting tool. |

هquipment process flow

Sheet supply → Sheet transport → First heating stage → Second heating stage → Forming and cooling → Cutting → Separation and stacking → Waste material rewinding system

Note: The production line consists of three workstations. The operation mode can switch between manual and automatic, with manual operation facilitating sample extraction and parameter setting control.

هquipment technical description

A. Forming Equipment Structure:

The forming equipment consists of the main structural frame, positive and negative pressure forming system, temperature control system, vacuum system, heating system, pneumatic control system, electrical and PLC control system, punching system, product decomposing robotic arm stacking, and automatic waste material rewinding system.

B. Main Body Structure:

The main body is assembled from square tubes and channel steels, welded together to form the structure that supports heating, mold forming, mold punching, mold cutting, and auxiliary devices. The steel frame structure is designed following Structural Process Design, ensuring all involved parts meet the following standards: high-quality material selection, blank production methods, machining, heat treatment, part assembly, machine operation, and maintenance processes. This guarantees sufficient strength and rigidity for movable devices that transmit and convert motion and force. All metal surfaces are treated with anti-rust coating and base layer anti-corrosion paint. Standard components are used in the structure for easy maintenance and future part replacement.

C. Mold Table Structure:

The bottom servo motor cam lever linkage drives the hard tooth gear reducer, and the top servo motor cam lever linkage drives the same system.

D. Electrical and PLC Control System / Safety Features

نظام التحكم الكهربائي:

The electrical control system uses a PLC integrated module, with an industrial touch display as the HMI (Human-Machine Interface) featuring a Chinese interface. The machine includes button controls for operation and settings, as well as the ability to modify all process parameters, making it easy to operate and maintain.

Working Mode:

The machine operates in both manual and automatic modes. All settings and operations are handled via the touch display. After the operator places the material, pressing the “automatic” button starts the full process of thermoforming until the material in the hopper is processed. Manual mode is primarily used for mold changing or sample control.

Safety Measures:

The system includes multiple protection measures, with interlocking and closed-loop control to prevent collisions between moving parts.

The safety door is designed for manual locking and opening, and includes an integrated safety light curtain to enhance device safety, ensuring personnel and property safety.

Electrical Cabinet:

The electrical cabinet contains protective circuits, including overcurrent, overvoltage, undervoltage, short-circuit, and overload protection. The heating elements have fuse protection. For safety concerns that may pose a hazard to the system or parts, warning labels or notes are included. The control cabinet has 10% reserved space for future expansion of additional forming functions. The cabinet is equipped with filters and protective cooling fans.

Cables and Wiring:

All non-moving cables and wiring outside of power boxes are hidden in cable ducts, making it easier to access for repairs. If this is not possible, flexible hose fixation is used.

Emergency Stop Function:

Multiple “emergency stop” buttons are installed at the front, middle, and rear of the equipment. The emergency stop button immediately cuts off the power supply, ensuring no dangerous situations arise during emergency stops.

صالمنتجات المكررة

أنوبة شينجان

شركة شنغان (شنغهاي) للمواد الجديدة المحدودة – شريكك في حلول التغليف البلاستيكية

تأسست ShengAn في عام 2018 في شنغهاي، الصين، وهي شريك عالمي رائد مكرس لتقديم حلول متكاملة لصناعة التعبئة والتغليف البلاستيكية. بدءًا من المواد عالية الأداء وحتى المنتجات النهائية والآلات، نقوم بتمكين الشركات في جميع أنحاء العالم.

حلولنا الشاملة

- صفائح بلاستيكية متقدمة: نحن متخصصون في مجموعة كاملة من الصفائح البلاستيكية الحرارية، بما في ذلك APET، وRPET (PET المعاد تدويره)، وPETG، وPP، وPS، وGAG، وآمن ESD المواد، وتلبية التطبيقات المتنوعة والمتطلبة.

- المنتجات النهائية المخصصة للطعام: نحن نتجاوز المواد الخام لتصنيع عبوات عالية الجودة ومصممة خصيصًا، مثل صواني بلاستيكية صالحة للطعام، وأكواب يمكن التخلص منها & الأغطية، وتغليف نفطة مخصصة بالحرارة.

- آلات موثوقة & معدات: لإكمال دورة الإنتاج الخاصة بك، نحن نوفر وندعم بكفاءة ماكينات تشكيل الأكواب الحرارية PET وماكينات تعبئة الفقاعة.

جودة معتمدة، معايير عالمية

يتم التحقق من صحة التزامنا من خلال الشهادات الدولية مثل ISO 9001، FSSC، FDA، وGRS، مما يضمن أن منتجاتنا تلبي المتطلبات الأكثر صرامة للجودة وسلامة الأغذية والاستدامة.

لماذا الشراكة مع ShengAn؟

- التكامل الشامل: نحن نقوم بتبسيط سلسلة التوريد الخاصة بك من خلال تقديم كل شيء بدءًا من المواد وحتى الآلات، مما يضمن الاتساق والكفاءة والفعالية من حيث التكلفة.

- الالتزام بالجودة & أمان: إنتاجنا مدعوم بشهادات دولية صارمة، بما في ذلك ISO 9001، ISO 14001، FSSC، FDA، HACCP، وGRS (لـ RPET)، ضمان المنتجات التي تلبي أعلى المعايير العالمية.

- التميز التصنيعي المُثبت: وبدعم من قواعد الإنتاج الإستراتيجية الخاصة بنا في شنغهاي، فإننا نمتلك القدرة على تقديم حلول موثوقة وقابلة للتطوير وإدارة سلسة لسلسلة التوريد للعملاء في جميع أنحاء العالم.