ورقة الحيوانات الأليفة المضادة للحاجز

Intro of Anti-block PET Sheet

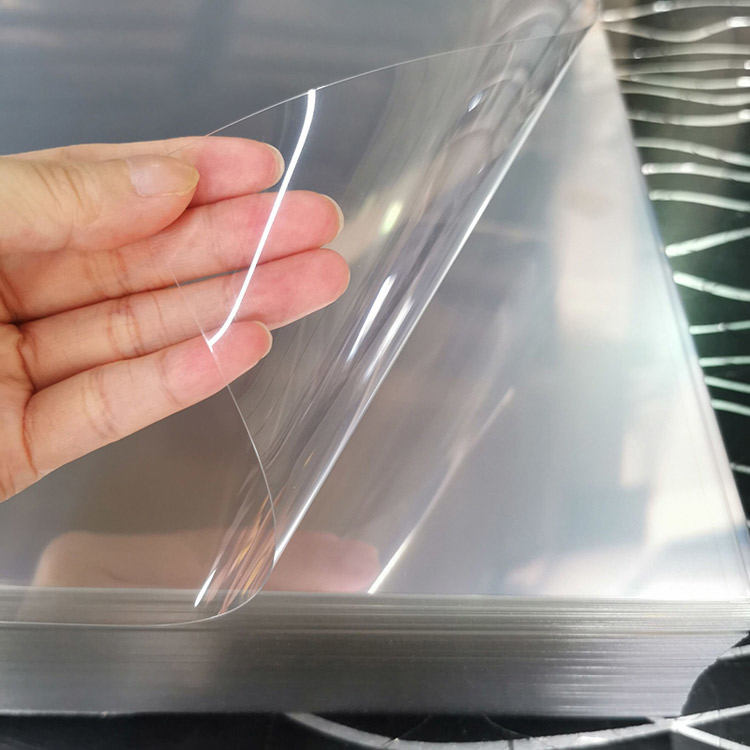

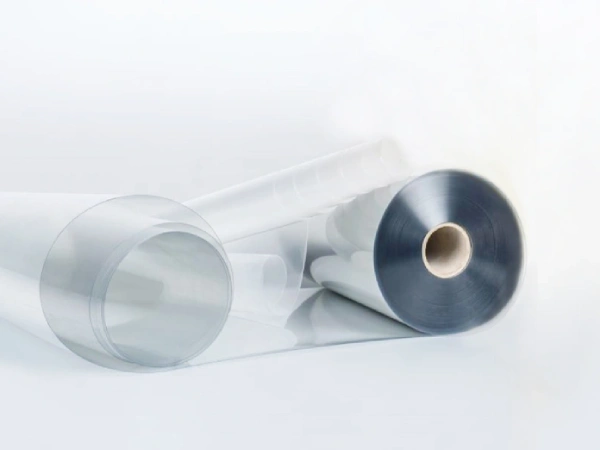

Anti-block PET sheet is a specially treated polyethylene terephthalate (PET) film or sheet, mainly used to prevent blocking of materials when stacking or winding. Anti-blocking technology is usually implemented in two ways:

External Silicone Coating: Coat a layer of silicone oil on the PET surface to reduce the surface friction coefficient.

Internal Slip Additive: Add a slip agent (such as silica, silicone or wax) during the production process to make it evenly distributed in the PET substrate.

The product thickness usually ranges from 0.18mm to 1.7mm and is suitable for industrial applications that require high transparency, temperature resistance and anti-blocking properties.

| مواصفة | Silicone oil-coated PET | Embedded anti-block PET |

| لون | Any customized color | Any customized color |

| مادة | PET/R-PET | PET/R-PET |

| Surface treatment | Silicon-coated | Non-silicon / Embedded |

| عرض | 250-1400(mm) | 250-1400(mm) |

| سماكة | 0.18-1.7(mm) | 0.18-1.7(mm) |

| Density | 1.34g/cm3 | 1.34g/cm3 |

Features of Anti-block PET Sheet

- Excellent anti-blocking performance: effectively prevent PET sheets from sticking when stacking or winding.

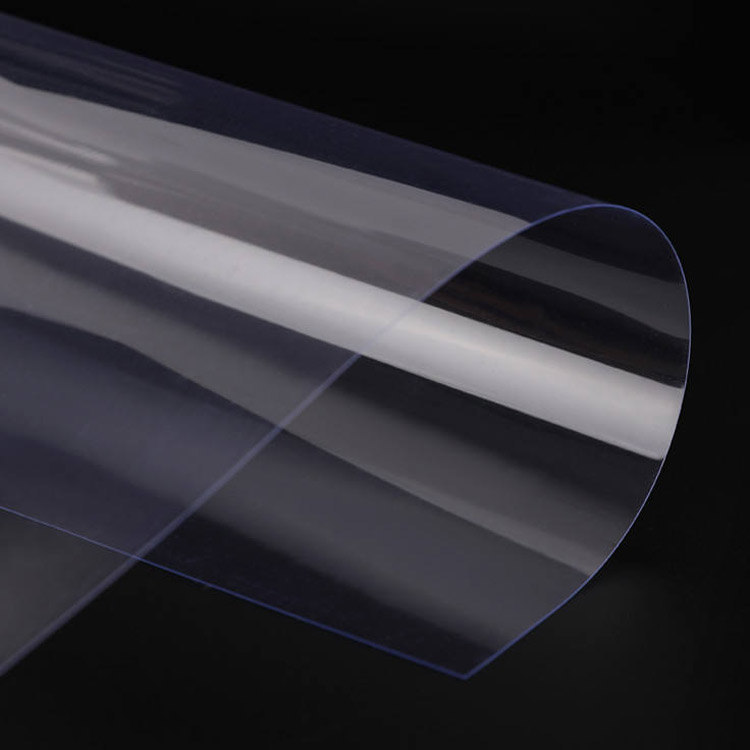

- High transparency (for external silicone oil coating): The silicone oil coating is extremely thin and has almost no effect on optical properties.

- Good slipperiness (internal type): Low friction coefficient, easy processing and separation.

- Temperature resistance: PET substrate can withstand -40°C to 150°C (higher in the short term).

- Chemical stability: Resistant to oil, grease, weak acid and weak alkali, suitable for a variety of industrial environments.

- High mechanical strength: Anti-stretching and anti-puncture, suitable for die-cutting, stamping and other processing methods.

Advantages of Anti-block PET Sheet

| Comparison item | External silicone oil type | Internal slip type |

| Anti-stick effect | Excellent, suitable for high-demand scenarios | Good, may slightly decrease with long-term use |

| الشفافية | High (very thin coating) | May be slightly lower (depending on additives) |

| Permanence | May be weakened by friction or cleaning | More durable (slip agent is evenly distributed) |

| Applicable process | Suitable for short-term anti-stick needs | Suitable for long-term storage or high temperature environment |

| Cost | Higher (additional coating process required) | Lower (direct production) |

Comprehensive advantages:

✔ Reduce production downtime (avoid material adhesion affecting processing)

✔ Improve automated packaging efficiency (sheets are easy to separate)

✔ Applicable to industries with high cleanliness requirements such as food and medical

Applications of Anti-block PET Sheet

- Packaging industry: food tray gasket, high-end gift box anti-sticking layer

- Electronic industry: display screen protective film, lithium battery separator

- Medical industry: tablet packaging, medical device anti-sticking pad

- Industrial materials: composite material isolation film, die-cutting and stamping pad

- Printing industry: high-gloss PET printing anti-sticking backing paper

التعليمات

PET sheet type we offer

| PET sheet type | Width (mm) | Thickness (mm) | لون | Resistance value (Ω) |

| Silicon-coated PET | 300-1400 | 0.18-2.0 | Transparent/Others | / |

| RPET sheet | Transparent/Others | / | ||

| GAG sheet | Transparent/Others | / | ||

| Anti-fog PET | Transparent/Others | / | ||

| High impact PET | Transparent/Others | / | ||

| PET lamination PE | Transparent/Others | / | ||

| PET sheet for electronic | ||||

| Conductive PET | 300-1400 | 0.18-2.0 | Transparent/Others | 104-106 |

| Semi-conductive PET | Transparent/Others | 106-109 | ||

| Anti-stactic PET | Transparent/Others | 109-1011 | ||

| Coated PET | Transparent/Others | 103-106 | ||

أنوبة شينجان

شركة شنغان (شنغهاي) للمواد الجديدة المحدودة – شريكك في حلول التغليف البلاستيكية

تأسست ShengAn في عام 2018 في شنغهاي، الصين، وهي شريك عالمي رائد مكرس لتقديم حلول متكاملة لصناعة التعبئة والتغليف البلاستيكية. بدءًا من المواد عالية الأداء وحتى المنتجات النهائية والآلات، نقوم بتمكين الشركات في جميع أنحاء العالم.

حلولنا الشاملة

- صفائح بلاستيكية متقدمة: نحن متخصصون في مجموعة كاملة من الصفائح البلاستيكية الحرارية، بما في ذلك APET، وRPET (PET المعاد تدويره)، وPETG، وPP، وPS، وGAG، وآمن ESD المواد، وتلبية التطبيقات المتنوعة والمتطلبة.

- المنتجات النهائية المخصصة للطعام: نحن نتجاوز المواد الخام لتصنيع عبوات عالية الجودة ومصممة خصيصًا، مثل صواني بلاستيكية صالحة للطعام، وأكواب يمكن التخلص منها & الأغطية، وتغليف نفطة مخصصة بالحرارة.

- آلات موثوقة & معدات: لإكمال دورة الإنتاج الخاصة بك، نحن نوفر وندعم بكفاءة ماكينات تشكيل الأكواب الحرارية PET وماكينات تعبئة الفقاعة.

جودة معتمدة، معايير عالمية

يتم التحقق من صحة التزامنا من خلال الشهادات الدولية مثل ISO 9001، FSSC، FDA، وGRS، مما يضمن أن منتجاتنا تلبي المتطلبات الأكثر صرامة للجودة وسلامة الأغذية والاستدامة.

لماذا الشراكة مع ShengAn؟

- التكامل الشامل: نحن نقوم بتبسيط سلسلة التوريد الخاصة بك من خلال تقديم كل شيء بدءًا من المواد وحتى الآلات، مما يضمن الاتساق والكفاءة والفعالية من حيث التكلفة.

- الالتزام بالجودة & أمان: إنتاجنا مدعوم بشهادات دولية صارمة، بما في ذلك ISO 9001، ISO 14001، FSSC، FDA، HACCP، وGRS (لـ RPET)، ضمان المنتجات التي تلبي أعلى المعايير العالمية.

- التميز التصنيعي المُثبت: وبدعم من قواعد الإنتاج الإستراتيجية الخاصة بنا في شنغهاي، فإننا نمتلك القدرة على تقديم حلول موثوقة وقابلة للتطوير وإدارة سلسة لسلسلة التوريد للعملاء في جميع أنحاء العالم.